Formula 1 teams have long tried to figure out the best product for ensuring precise fuel flow measurements as it is essential to quality performance.

Over the past few seasons, more and more F1 teams have questioned the fuel flow figures being returned from their engine suppliers fuel management systems.

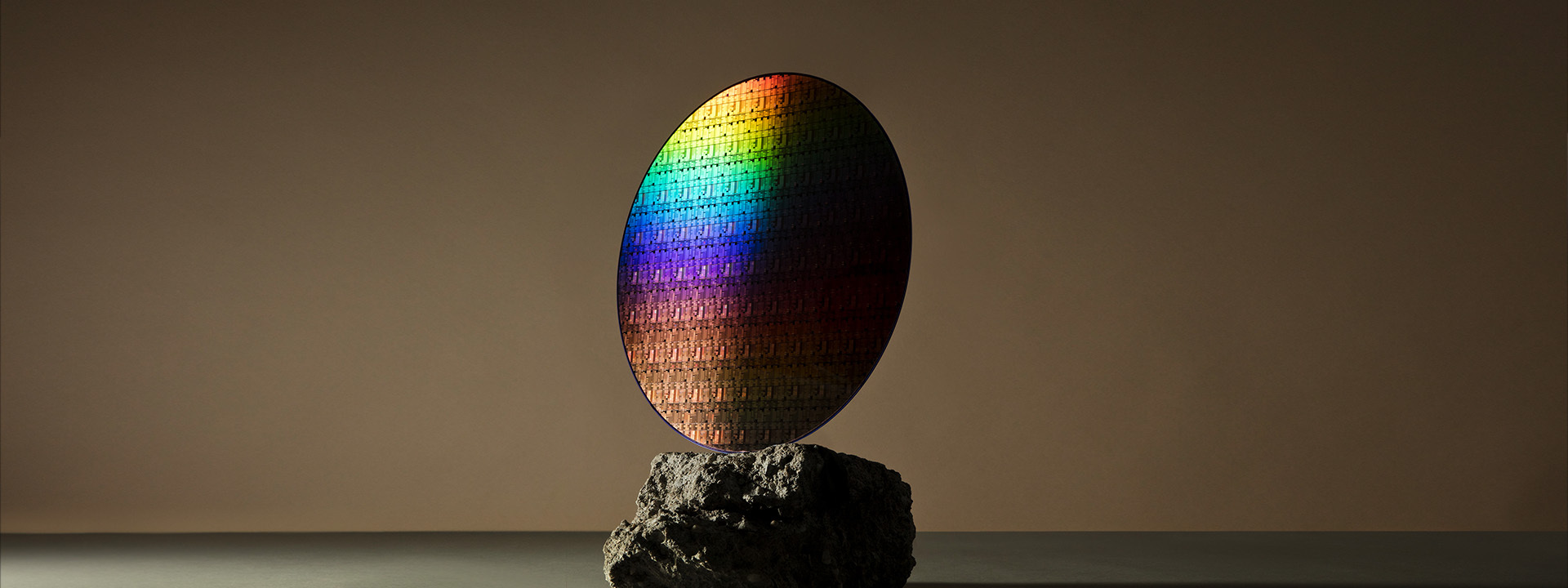

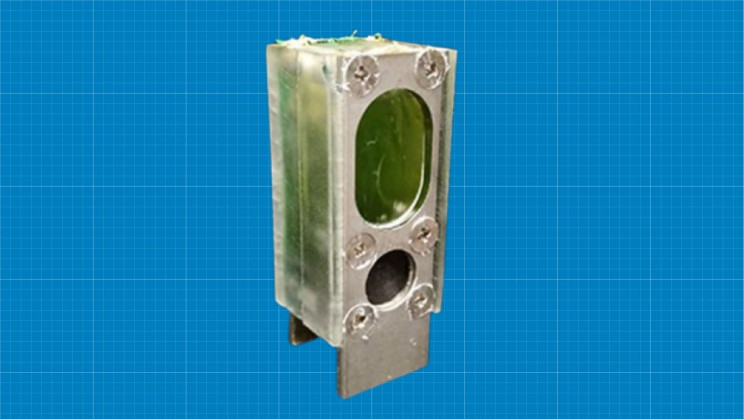

As a result, Titan Enterprises designed a very lightweight oval gear flow meter to be installed safely in the fuel tank of the racing car. The flow meter was designed to be immune to immersion in fuel and the noisy electrical environment of an F1 racing car, capable of providing accurate flow measurement over an extended period of time.

Titan high pressure flow meters have been widely used in the hydraulic systems of F1 racing cars to measure fluid flow, not to mention being utilized to monitor the oil flow lubricating turbo units on the test bench for high performance engine companies.

Formula 1 engines typically have no cooling fans and therefore need to reliably run at temperatures in excess of 200°C. Measuring the high flow of coolant water at these elevated temperatures without causing an undue pressure drop in the system was a major issue that thankfully was resolved by Titan.

Using the inherent very low pressure drop of their Oval gear flow meter design – Titan produced a 200°C, 50 L/minute flow meter with a pressure drop of less than 100mBar.

As the 2014 Formula 1 season gets underway with a host of new vehicles, engines, and rules, it is a luxury for F1 teams to be able to focus on racing and not the accuracy and sustainability of their flow meters.

More accurate fuel flow measurement results in a more precise fuel management system over the duration of a race, giving a team the ultimate advantage to win a race.