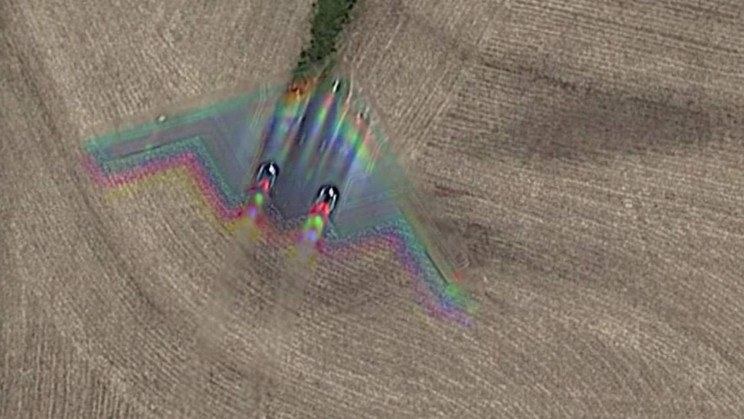

Britain’s National Physical Laboratory has designed and developed a new high temperature ceramic capacitor in hopes of improving the use of electric and hybrid vehicles, which could mean that the vehicles can travel much greater distances on one battery charge.

Electric or hybrid vehicles all need the necessary cooling equipment because of limitations in the temperature rating in many components like capacitors that store electrical energy. As a result, additional cooling systems are required in the vehicle, which all add weight and hamper its power and efficiency.

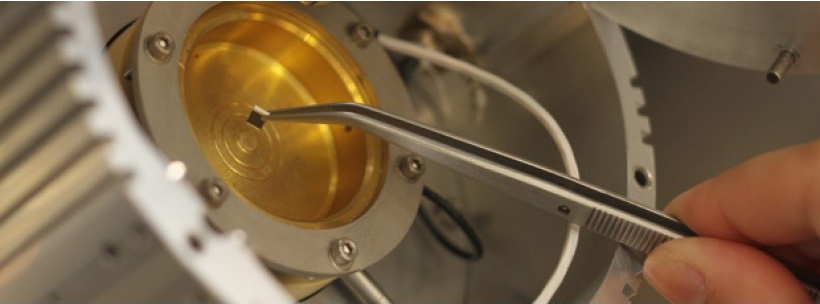

In response to this, the NPL has developed a ceramic capacitor dielectric material that has a high energy density. The material, HITECA, can operate at temperatures of up to 200 degrees Celsius.

Tatiana Correia is a Higher Research Scientist in Functional Materials at NPL and was the leader behind the research. “Industrial electronics need to be able to perform in the harsh environments in which they operate,” she says. “The ability of HITECA capacitors to function at higher temperatures than existing capacitors will help make electronic systems more robust and remove barriers for technologies such as electric vehicles that rely on them.”