In April 2015, a Norwegian Floating Production, Storage and Offloading vessel (FPSO) requested a solution to rebuild, strengthen and protect corroded gas pipes. A series of pipes on board the North Sea FPSO were displaying signs of corrosion between both the pipe and support, in some areas registering thin wall defects with up to 35% wall loss. Not only did this represent a severe containment issue, but it also threatened the vessel’s operation.

Impressively, FPSOs combine facilities for production, processing, and storage all in the same place. Often viewed as a safer and more economical solution, with the ability to relocate to another development, these vessels have become the foremost system for offshore oil and gas production. Receiving material from subsea reservoirs, it is then processed before being stored on board, until it is possible to offload elsewhere via tanker or through pipelines. These pipes often suffer severe corrosion at support points due to abrasion and/or galvanic corrosion. This can have destructive effects on the wall’s integrity, quickly developing into thin and even through-wall defects.

In this situation, the customer highlighted how the 6” gas pipe system was suffering from corrosion between the pipe and support. Significantly, the hazardous part of the project was lifting the pipes because of internal pressures; therefore, in order to eliminate the associated risks, the project needed to be executed offline. In order to limit the downtime of the FPSO, the asset owner assigned a limited shutdown period, totalling 7 days.

Because welding was not an option, the application required a unique cold applied solution due to the total number of irregular pipe geometries, incorporating a well-engineered design, for both Tee junctions and sharp bends. Consequently, the customer selected Belzona SuperWrap II, because of the composite wrap’s versatility and ability to conform to complex geometries. Having previously worked with the Belzona Distributorship in Norway, CAN AS, the customer received a precise timeline for the applications, overall guaranteeing an efficient and structured process. Within this time, five of the days were specified for the design and installation of all six repairs, whilst the remainder allowed for curing and demobilisation of all equipment and personnel.

The application was carried out in accordance with ISO/TS 24817 and ASME PCC-2 Article 4.1., certifying the composite wrap system in line with equipment and piping repair regulations, for petroleum, petrochemical and natural gas industries. Prior to the installation, heavy equipment was rigged into place, necessary for lifting the large sections of pipe, consistent with engineering designs. Notably, some areas needed the use of rope access techniques, requiring an overall team of five operators, including riggers, inspectors and product specialists.

In order to determine the extent of the defect, ultrasound equipment was used to inspect the status of the damaged pipework. Eventually, this revealed areas where more than a third of the substrate had succumbed to thin wall corrosion, thus demanding reconstruction of the pipeline surface before the application of Belzona SuperWrap II. As a part of the designated plan, the installation team assembled tarpaulin housing around the specific pipe defect, for grit blasting and climate control purposes. Each wrap application followed the same procedures, by initially grit blasting in accordance with Standard SA2.5, removing any foreign corrosive matter. Ultimately, this provided an optimum substrate surface profile of 75µm, ideal for successful application. Once achieved, corrosion resistant Belzona 1111 (Super Metal) was used to rebuild the metal substrate. The versatile adhesive properties of the resurfacing epoxy-based composite, particularly on carbon steel substrates, created a level surface for the next stage of repair.

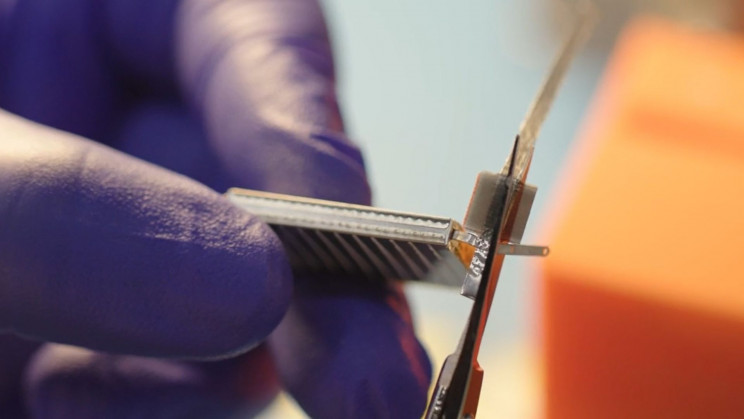

As highlighted, the complex pipe geometries included bends, straights and tees, necessitating a tailored design for the Belzona SuperWrap II application. The two-part, fluid grade resin system works in conjunction with a bespoke hybrid reinforcement sheet based on fibre glass and carbon fibre. The fibre glass offers flexibility, in addition to serving as a wet-out indicator, which ensures effective application of the reinforcement sheet. Interwoven with carbon fibres, the reinforcement sheet provides the composite wrap with the strength it needs to retain high pressures and loads. Belzona were able to cut the reinforcement sheets to match the unique pipe dimensions in the form of reinforcement jackets for the tees, whilst utilising specifically measured strips for the bends. Before each application, the substrate was wetted with the fluid grade resin system, maximising the bond between the carbon steel and Belzona SuperWrap II. Covering lengths of 690mm, applicators used seven spirals of reinforcement around each defect, creating a tapered profile of 14mm at the densest section. Finally, this was consolidated by tightly wrapping release film around the composite wrap, which was later removed after the cure process was complete, allowing the repair to securely adhere.

Following completion of the Belzona SuperWrap II installation, a new solution was implemented to place the pipes into position, fit for purpose. Belzona 1311 (Ceramic R-Metal) was adapted by applicators to create irregular loading bearing shims between the pipeline and support. Often used for metal repair and protection against the effects of erosion and corrosion, these reinforced plates were installed to transfer the load of the pipe, demonstrating the material’s excellent compressive strength.

Inclusive of grit blasting the defected areas, each Belzona SuperWrap II installation was finished within 6 hours, leaving sufficient cure time for each application. Once the entirety of the repair was completed, it was necessary for pressure testing to be carried out. After successful assessment indicated that the pipe pressure had been restored to its original levels, without any irregularities, the pipe system was set back into production. Due to the initial planning, combined with the correct equipment and application management, there were no issues during the timeline of the project, consistent with the customer’s specified shutdown period.

Primarily, all phases of the project were handled by one contractor, allowing for a consistent approach that ensured the application was successfully achieved within the allotted schedule. Furthermore, this was significantly aided by the ease and speed in which Belzona’s versatile composite wrap system could be applied. Since installation, the customer has indicated that the application is functioning well and is set for periodic inspection, in line with the specified design life of 20 years. Between 2010 and 2015, a total of 48 Belzona SuperWrap applications have been commissioned by the customer, across various offshore oil and gas platforms. This figure has subsequently risen, after three repairs executed in August 2015 were completed, serving as an indication of the product’s strength and the customer relationship developed.