Working in the electrical industry comes with inherent risks. From the perils of high voltage shocks to the threat of fires and explosions, it is an environment where safety protocols cannot be taken lightly. This document aims to shed light on the common dangers faced by electricians and other industry professionals, providing practical strategies for mitigating risks.

Whether it’s through comprehensive training, adoption of the latest safety gear, or a culture of vigilance, understanding how to navigate these hazards effectively can be the difference between a normal workday and a life-threatening situation. Keeping safety at the forefront is not just a regulatory requirement; it’s a fundamental responsibility of every individual in the field.

Understanding Electrical Shock Risks

Electrical shock is one of the most prevalent dangers in the electrical industry. It occurs when an individual comes into contact with an energy source, and the electrical current passes through the body. The severity of the shock can vary greatly and may cause anything from minor discomfort to severe injury or death. To minimize the risk of electrical shocks, workers should always ensure that the power is turned off before beginning any work and double-check with a voltage tester. Repeated exposure to live circuits can lead to complacency, which in turn increases the risk of accidents.

Therefore, ongoing safety education and awareness are crucial. Workers should be drilled regularly on the correct lockout/tagout procedures to ensure that all energy sources are properly isolated before any repair or maintenance work is attempted. Also, inspection tags should be used to indicate that equipment is being serviced, and workers should never assume that an electrical switch or outlet is safe just because it’s been turned off. Not only can this lead to accidents, but it’s also in violation of OSHA regulations.

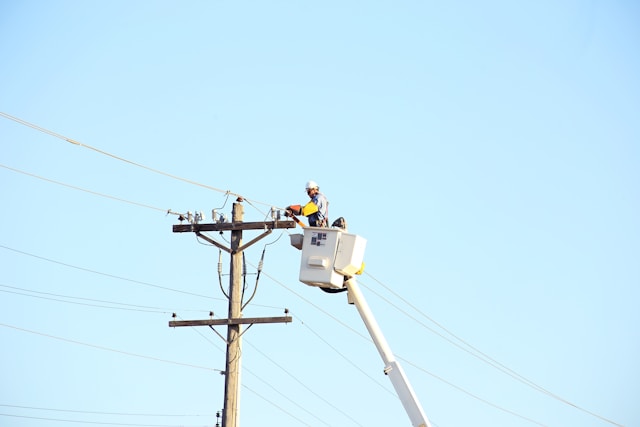

Preventing Falls and Trips

Working in the electrical industry often involves navigating cluttered spaces or working at heights. Falls and trips can be especially dangerous in these environments. Proper housekeeping, clear labeling of hazards, and the maintenance of clear work areas are essential prevention strategies. Workers should always use fall arrest systems and maintain three points of contact when climbing ladders or scaffolds to lessen the probability of accidents.

Training programs should also emphasize the importance of situational awareness. Electricians must be conscious of their surroundings at all times, and aware of potential risks posed by loose cables, tools left on the ground, or unstable surfaces. Regular safety briefings can serve to reinforce this aspect of workplace culture, reminding employees to be vigilant and observant.

Fire and Explosion Prevention

Due to the nature of the work, there is always the risk of fires or explosions in the electrical industry. These can result from short circuits, overloaded systems, or the improper storage of flammable materials. It’s imperative that electrical systems are regularly inspected for signs of damage or wear and that any anomalies are addressed immediately. Electrical professionals should also be well-versed in the types of fire extinguishers and their correct usage.

Understanding the unique fire risks associated with different electrical components and environments is fundamental. For instance, the potential for arc flashes—an electrical explosion produced by a low-impedance connection—can be mitigated by using arc-resistant switchgear and wearing protective clothing. Workers should be trained not only on how to prevent these incidents but also on how to respond should they occur.

Risk Management with High Voltage Equipment

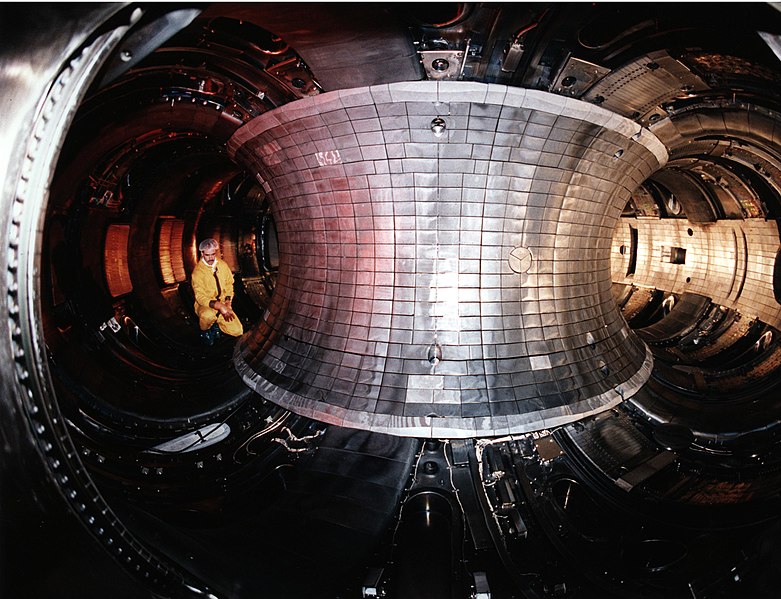

High-voltage equipment presents significant inherent risks due to the large amount of energy involved. Specialized training is a must for any personnel working with or near high-voltage systems. This includes protocols around approaching the equipment, using the appropriate tools, and understanding the distances that need to be maintained to ensure safety.

Beyond training, engineering controls can be employed to enhance safety around high-voltage equipment. This can include the installation of barriers, insulation of electrical components, and ensuring equipment is as per the latest safety standards. Regular equipment testing and maintenance are also a part of effective risk management to prevent catastrophic failures.

Use of Personal Protective Equipment (PPE)

The correct usage of Personal Protective Equipment (PPE) is a straightforward yet critical measure to enhance safety in the electrical industry. PPE such as insulated gloves, dielectric footwear, hard hats, and arc-flash-rated clothing reduce the risk of electrical burns and shock. Moreover, Safety glasses or face shields protect against flying debris and sparks when cutting wire or during other tasks.

Regular PPE inspections are vital to ensure that all equipment is in good condition and offers the protection it should. Workers should be familiar with the life expectancy and limitations of their PPE, with training on how to properly put on, use, and take off the protective gear to maximize its efficacy.

Cultural Safety and Teamwork

Cultivating a strong safety culture within a team can significantly reduce the risk of accidents in the electrical industry. This includes promoting an environment where communication is open, and individuals feel comfortable reporting hazards or near-misses. Teamwork also plays a key role, with more experienced workers mentoring younger staff and teams conducting hazard assessments together before starting a project.

Regular team meetings focused on safety can help to maintain this culture, allowing for the discussion of best practices, changes in regulations, or introductions of new technology. Leadership needs to be involved in these discussions to underscore their commitment to safety and to set the tone for the team.

Continuing Education and Safety Training

The electrical industry is constantly evolving with new technologies and standards. Continuous education and up-to-date training remain imperative to stay abreast of these changes and to maintain a safe working environment. This includes regular updates on local and national safety regulations, hands-on training with new equipment, and refreshers on emergency response procedures.

An investment in skills development and knowledge sharing can prevent accidents by keeping safety at the forefront of workers’ minds. Electricians who are well-informed about the latest practices and technologies can not only work more safely but also more efficiently, reducing the likelihood of potentially dangerous shortcuts or oversights.

In conclusion, the electrical industry, while indispensable to our modern lifestyle, is fraught with significant dangers that professionals must navigate daily. From the risk of electrical shock and falls, to the serious threats of fires and explosions, to the challenges of managing high-voltage equipment, the responsibility to maintain safety is tremendous. Personal Protective Equipment is a critical line of defense, but it is the cultivation of a robust safety culture and the commitment to teamwork and continuous education that truly make the difference.