‘Britishvolt’, the UK investors-backed start-up that is aspiring to build a massive battery manufacturing plant (“gigafactory”) in Northumberland, has just taken a very important step in bolstering its plans. The company has signed a deal with Glencore who agreed to provide them with cobalt in the long term.

Cobalt is a key ingredient in EV batteries, so you cannot operate a gigafactory without a stable supply of the material. Mining companies like Glencore source their cobalt from Congo where the world’s largest reserves exist. The Asian EV market explosion however sees 80% of all refined cobalt ending up in Chinese automakers, so finding enough supplies isn’t free of complications.

A thorn in the deal is that Glencore isn’t following the most ethical practices in its Congo mines, as there have been multiple reports about human rights abuses and the absence of health and safety measures in those workplaces. Some EV car manufacturers source their cobalt from elsewhere as doing business with the wrong parties can impact their market image and by extension their sales, but truth is, one doesn’t have many options right now.

Britishvolt had every reason to celebrate the sealing of the deal, as it makes the project far less likely to be derailed in the near future due to cobalt supply shortages. Also, they stated that they’ll ensure that the supply comes in an ethical manner, and with minimal impact to the environment, so they trust that Glencore has addressed all of the aforementioned issues. After all, the mining company is a strategic investor in Britishvolt, so it has a double incentive to do things right.

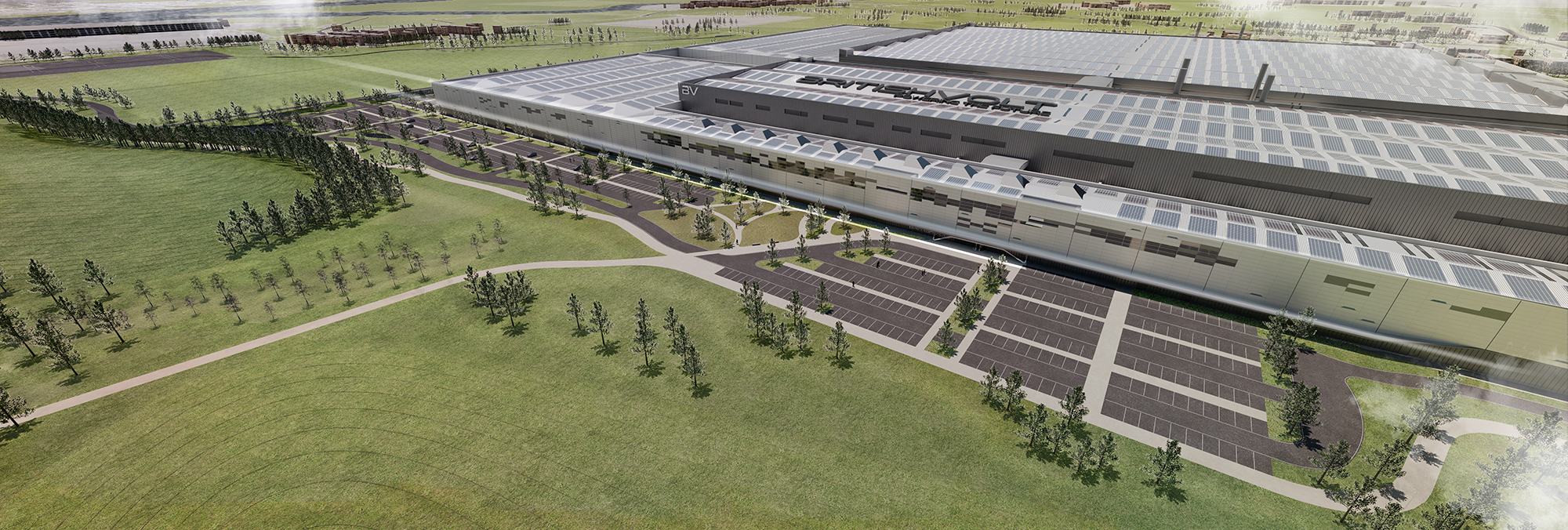

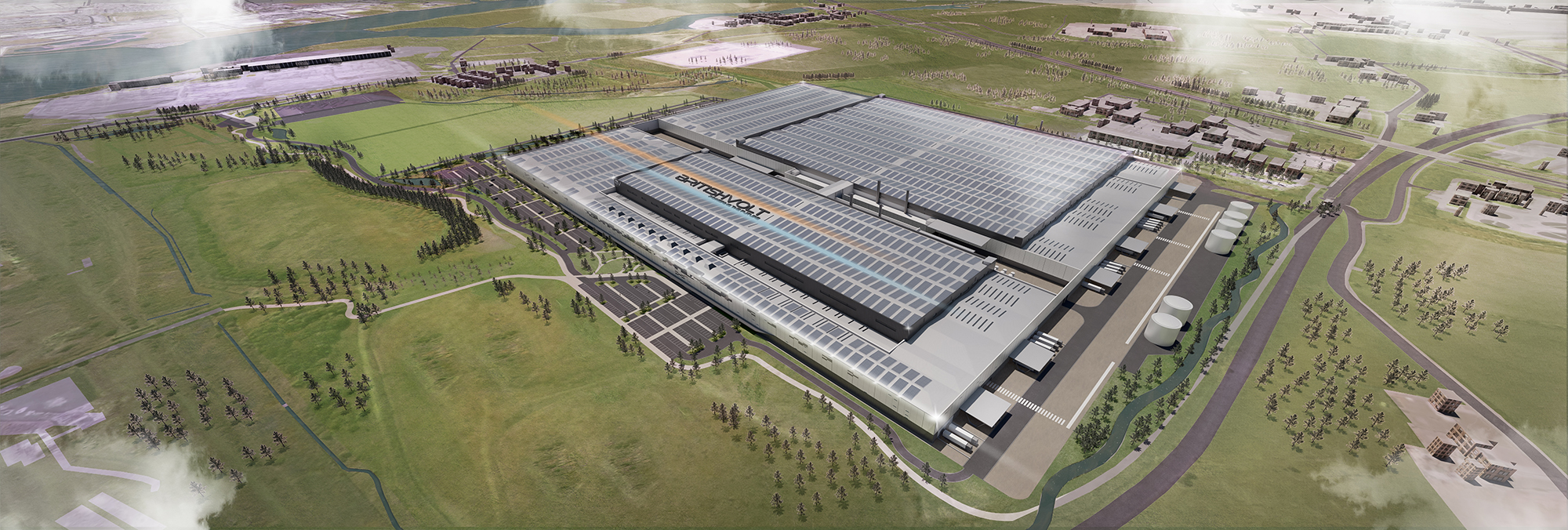

With that crossed off the list, the £4 billion project may resume its progress and the construction of the gigafactory can now begin. Once complete, it will produce 300,000 EV batteries annually and will employ 1,000 people, gradually taking that number up to 3,000.