An international team of researchers has developed wearable textile that repairs itself, is antibacterial, and could even monitor a person’s electrocardiogram (ECG) heart signals.

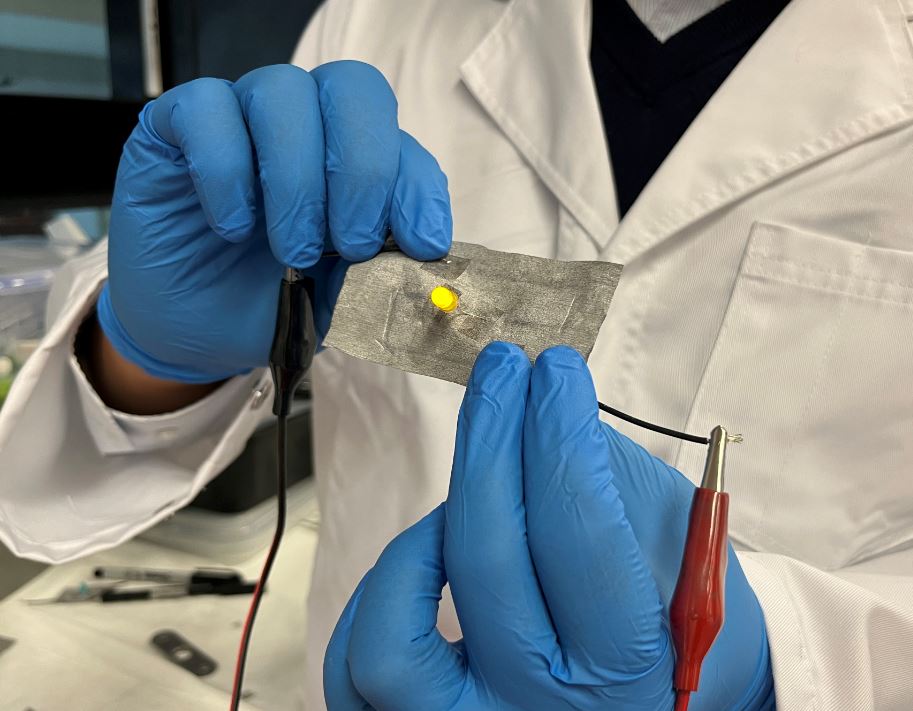

Researchers say developing this highly conductive textile is very simple. They just had to dip a clean piece of fabric in liquid metal (LM) particles at room temperature. Then they had to shake it in a solution for 45 minutes.

This liquid is a solution of the gallium and indium metals, suspended in isopropanol. Researchers foresee that the conductive circuits formed by liquid metal (LM) particles can revolutionize wearable electronics.

Potential applications in soft-robotics, wearable electronics, and health monitoring systems

By adding more coats, you can make the fabric more conductive. Moreover, the fabric has special connectivity powers to “autonomously heal” itself even when cut. This “makes these textiles useful as circuit interconnects, Joule heaters and flexible electrodes to measure ECG signals,” Vi Khanh Truong, co-senior author of a report said.

Moreover, the fabric also offers protection against potentially deadly bacterial infections from Pseudomonas aeruginosa and Staphylococcus aureus. The unique qualities of this textile make it fit for use in hospitals. Fabric can be used to create antimicrobial bedsheets and patient clothing. It could not only help prevent infections but will also monitor a patient’s heart.

The study was published in the journal Advanced Materials Technologies.

The following video demonstrates how textiles create new conductive pathways even after it’s cut: