A few months ago, we wrote an article about how igus’s plastic bearings were superior to metal in the automobile industry and that the company was going to have someone drive across the world in a car outfitted with igus iglide plastic bearings to prove it.

Recently, the igus iglide on tour car entered Los Angeles, California, after traveling through Japan, Taiwan, South Korea, China, India, Brazil, and Canada.

Igus is not simply claiming their plastic bearings are better than metal bearings, they are literally proving it with the iglide car as I write this.

But what if I told you plastic bearings being superior to metal bearings is not limited to the automobile industry?

Plastic Bearings Are Superior To Metal In The Bicycle Industry:

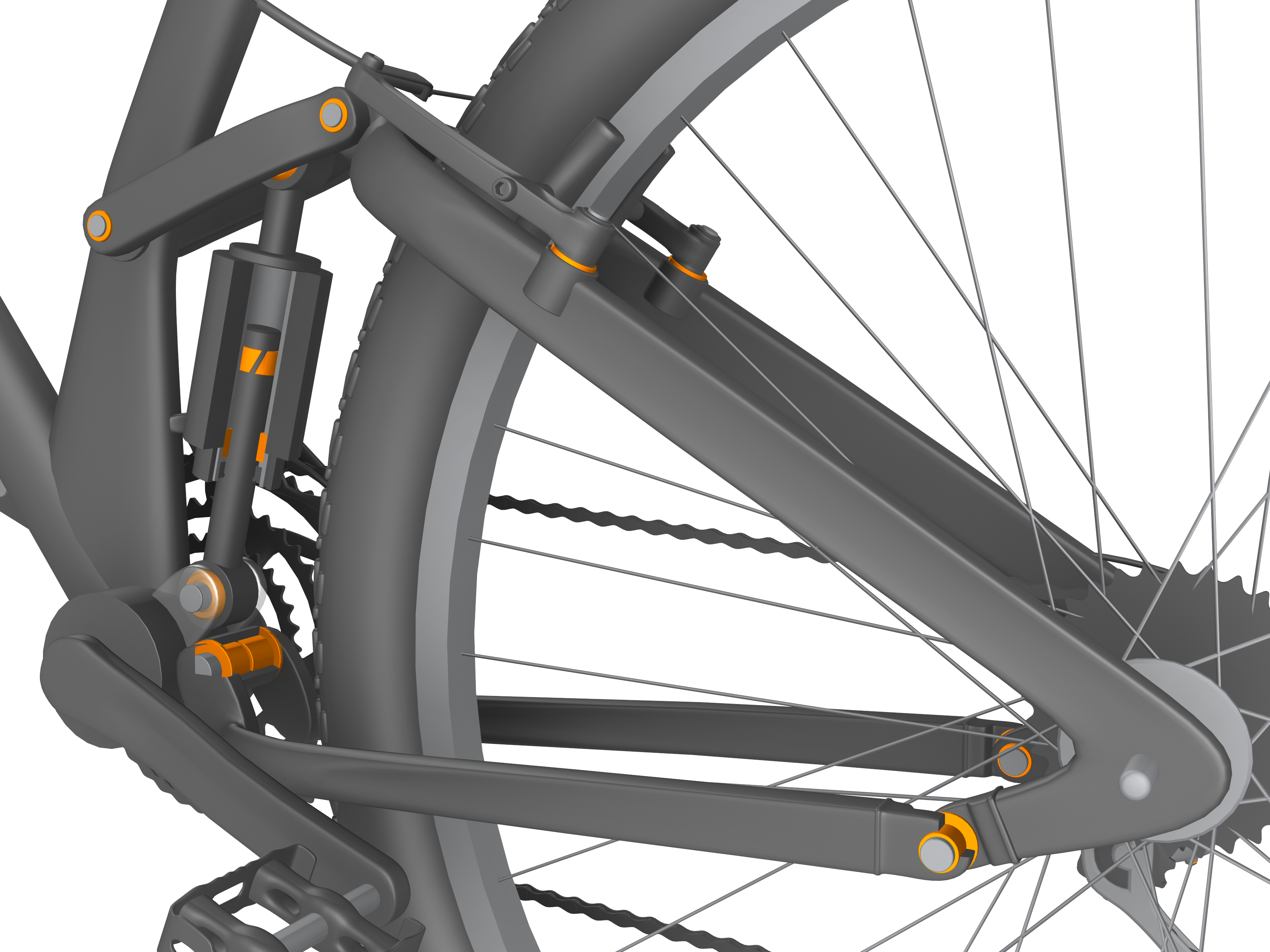

In fact, with all their advanced characteristics, iglide plastic bearings are a perfect choice for use in all sorts of bicycle applications, including in pedals, shocks, and suspensions.

Because of their light weight, bikers love plastic bearings! Bike manufacturers choose igus in their designs as well because of their special features, like vibration dampening properties and resistance to dirt, chemicals and water,

igus’ original iglide bearing material, iglide G300, is widely used by bicycle manufacturers, in bike shocks and pedals, because it helps alleviate long term costs, as well as maintenance costs. The G300 material is able to absorb high shock loads that occur when biking across mountainous, uneven terrain, and while traveling at high speeds. The G300 bearings are also able to handle very high loads, perfect in a bike’s pedals, absorbing the shock of the rider pedaling. This vibration dampening and load-absorption makes for a more comfortable ride for the customer.

Self-Lubricating Bearings Minimize Maintenance:

Perhaps the most unique aspect of igus’s iglide plastics bearings is the fact that they are self-lubricating, meaning there is no need for maintenance from the manufacturer or the customer. Those of you who have any experience riding on metal bearings know how annoying and tedious cleaning/maintenance can become once the metal starts squeaking or acting up.

Since you don’t have to apply grease or oil to iglide plastic bearings, there is also a lower chance of bearing seizure and rider injury. With metal however, lubricant can be washed away or compromised in extremely wet or dirty riding conditions and prove to be extremely dangerous. With self-lubricating plastic, dirt and water does not affect the coefficient of friction.

Even Olympic Level Cyclists Use Igus Bearings In Their Bikes!

Many Olympians, including Sabine Spitz, who took the gold in Beijing in 2008, use igus in their bicycles’ suspensions (Sabine’s bike used iglide plastic bearings in the suspension fork). At the Athens Olympics in 2004, mountain bikers riding bikes with lightweight igus plastic bearings took the gold, silver, and bronze medals.

You can’t compete with that!