Polymer coatings have applications in various industries, such as aerospace interiors and transportation. An array of advantages of changing surface properties was unknown until recently. However, leading experts in plain bearing technologies (GGB), recently made the surface solutions more efficient. In this article, we will explain the benefits of GGB’s newest line of tribological coatings, that are used in the automotive and industrial markets.

GGB – Experts in Innovative Plain Bearing Technologies

GGB, a champion in plain bearing technology, has provided the

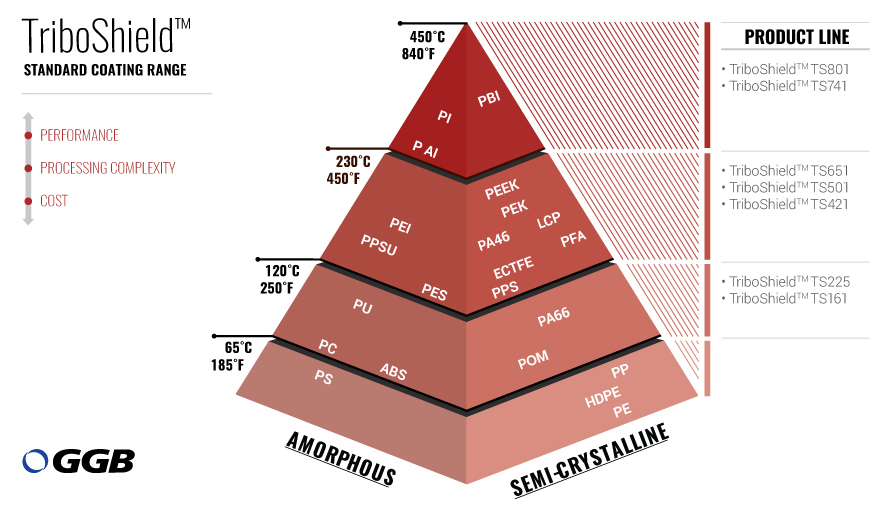

The company’s newest polymer coating material, TriboShield®, is set to revolutionize tribology solutions. TriboShield® polymer coating can coat any type of surface, so the product’s potential is nearly limitless. GGB’s far-reaching approach to surface engineering lets the customers have the highest standard performance in their respective industries.

The Benefits of Tribological Coatings

Simple Design

GGB’s polymer coatings have special friction levels for different sliding surfaces. It makes a simpler design with fewer parts. Moreover, the technology can reduce weight and save space due to less challenging requirements for surface finishing.

Coated Metallic Substrates

TriboShield® polymer coating can coat virtually every metallic substrate, which include aluminum, titanium, steel, stainless steel, magnesium etc. It can be used to coat composite and polymeric substrates as well.

Protection from Chemicals and Corrosion

GGB’s coating formulas protect surfaces against harsh chemicals and corrosion. The solution acts as an inert material barrier between surfaces. It extends the surfaces’ longevity and enhances their application performance.

Customization

Polymer coatings allow the customization for every customer’s needs. The highest standard of GGB’s surface engineering solutions makes the coatings easily tailored to the need of any application.

Self-Lubrication

Lastly, solid lubricants in GGB’s polymer coatings reduce or even eliminate the need for extra lubrication. The machine parts will stay cleaner and won’t contaminate nearby systems.

Tribological Performance

Reducing friction and extending the lifespan of industry systems is now possible with TriboMate™, which has up to 50% friction reduction in relative friction when compared to a standard tribological system. This upgraded tribological system also has a 75% wear reduction in relative wear compared to a standard system.

Systems’ performance improvement has been proven at GGB’s internal test rigs. Although your system performance may vary depending on speed, load, type of motion and temperature, GGB’s solutions have shown to improve the existing performance which takes your surface coating to the next level and makes your system last longer.

GGB’s tribological coating benefits include a simpler design, the option to coat metallic surfaces and various composite substrates, as well as protect surfaces from corrosion and chemicals. Your industry can also benefit from the high level of customization and self-lubrication properties not seen in traditional bearings. If you want to know more about tribological coatings, consult GGB’s experts in plain bearing systems and polymer coatings.