Addressing the Rubber Waste Challenge

Discarded tires are a major environmental concern, with over 274 million scrapped in the U.S. in 2021. Many of these end up in landfills, where they pose risks such as chemical leaching and fires. Traditional recycling methods, like pyrolysis, often produce toxic byproducts, making sustainable alternatives crucial.

Breakthrough by UNC Researchers

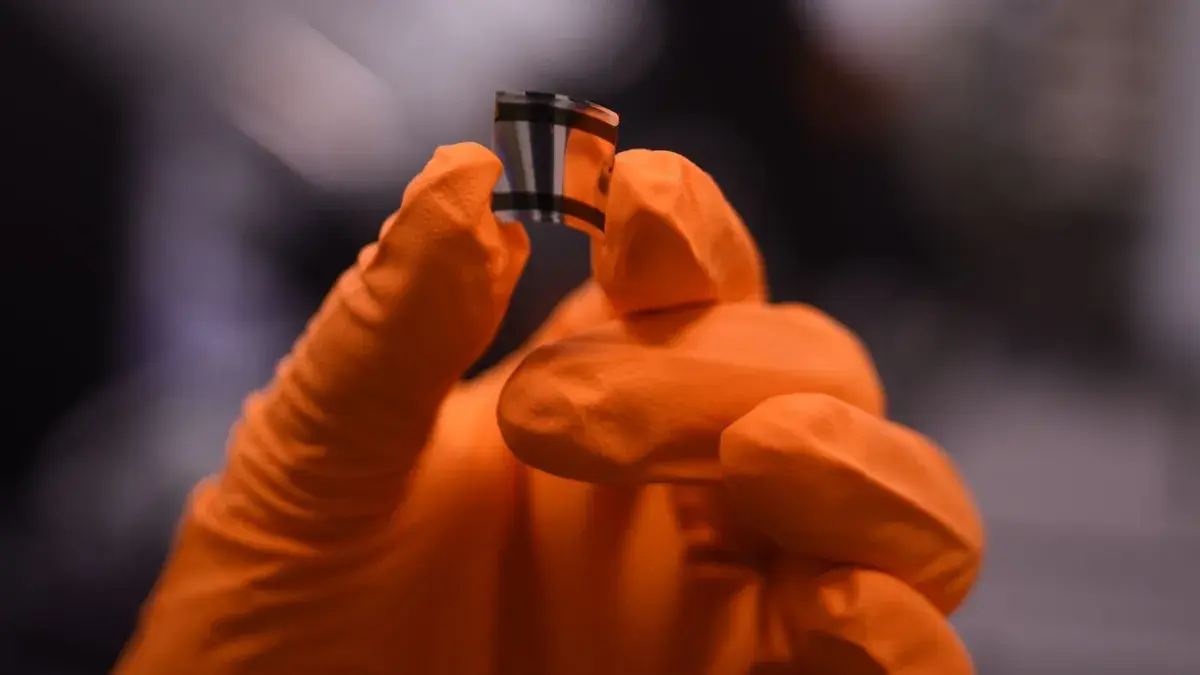

Scientists at the University of North Carolina at Chapel Hill, led by Dr. Aleksandr Zhukhovitskiy, have developed an innovative chemical process to break down rubber efficiently. Their method, detailed in Nature, utilizes C–H amination and polymer rearrangement to convert rubber waste into valuable epoxy resin precursors.

How the Process Works

Rubber’s resilience comes from its cross-linked polymer structure, which makes it difficult to degrade. UNC researchers introduced amine groups into these polymers using a sulfur diimide reagent, leading to a rearrangement that breaks the rubber into soluble materials. Unlike traditional de-vulcanization, this approach retains material strength and functionality.

Efficient and Eco-Friendly Results

The process dramatically reduces molecular weight from 58,100 g/mol to 400 g/mol, achieving complete breakdown within six hours at mild temperatures (35-50°C) in water-based conditions. This is a significant improvement over conventional recycling methods that require extreme heat or expensive catalysts.

A Step Toward Sustainable Materials

By converting waste rubber into strong, petroleum-free epoxy resins, this breakthrough offers a greener alternative to existing manufacturing processes. While further optimization is needed, this research marks a major step toward reducing landfill waste and developing sustainable materials.

Dr. Zhukhovitskiy believes this innovation could transform tire recycling, making rubber waste a valuable resource rather than an environmental burden.