Designed for both functionality and aesthetics, these durable concrete structures offer reliable solutions in demanding environments. They not only enhance the visual appeal of industrial and commercial spaces but also maintain their integrity over time. Through specialized manufacturing processes and high-quality concrete composition, they resist weathering, heavy loads, and environmental stressors while retaining their attractive appearance for years.

The combination of reinforced concrete and precise engineering enables decorative bin blocks to withstand extreme temperature variations, moisture exposure, and constant use. Their dual-purpose design serves storage needs while contributing to the professional appearance of facilities, making them particularly valuable for businesses that prioritize both practicality and presentation.

Workers can stack and arrange these solid barriers with confidence, knowing they will maintain their structural stability even when exposed to harsh weather conditions. The blocks’ weather-resistant properties and robust construction eliminate common concerns about degradation, making them a reliable choice for long-term outdoor applications.

Key Takeaways

- Decorative bin blocks resist environmental damage through specialized concrete composition and manufacturing methods

- These structures maintain both functionality and aesthetic appeal in challenging outdoor conditions

- The blocks provide lasting durability against weather exposure and heavy-duty use while enhancing facility appearance

Material Composition and Structural Integrity

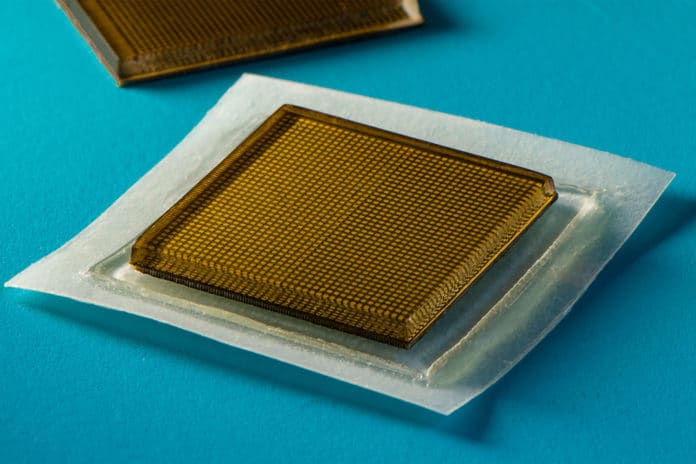

The durability of deco bin blocks stems from their high-quality concrete composition and innovative structural design features. Advanced manufacturing techniques create blocks that withstand extreme conditions while maintaining aesthetic appeal.

Concrete Block Essentials

Deco bin blocks utilize premium-grade concrete mixtures with specific ratios of cement, aggregates, and reinforcing materials. The concrete undergoes careful curing processes to achieve optimal strength ratings of 4000-5000 PSI.

The blocks feature steel reinforcement bars positioned strategically throughout the structure. This reinforcement prevents cracking and increases load-bearing capacity.

Water-resistant additives mixed into the concrete create a dense, non-porous surface that resists moisture penetration and freeze-thaw damage.

Incorporating Recyclable Materials

Steel slag and recycled concrete aggregate replace up to 30% of traditional materials in modern bin block production. These recyclable components maintain structural integrity while reducing environmental impact.

Post-industrial waste materials like fly ash enhance the concrete’s strength and workability. The addition of these materials creates stronger chemical bonds within the mixture.

Recycled steel fibres provide additional reinforcement throughout the block’s structure. These fibres increase tensile strength and impact resistance.

Interlocking Design for Enhanced Stability

Precision-engineered grooves and ridges allow blocks to connect securely. The interlocking system creates a unified structure that distributes weight evenly across connected units.

Blocks feature male-female connections that prevent shifting and separation. These connections maintain alignment even under heavy loads or environmental stress.

The interlocking design includes drainage channels to prevent water accumulation. This feature protects against structural weakening and frost damage in cold climates.

Special corner blocks incorporate angled surfaces for seamless connections. These specialized units maintain structural integrity around curves and corners.

Environmental Adaptability and Functional Uses

Deco bin blocks excel in diverse environmental conditions while serving multiple construction and landscaping purposes. Their robust concrete composition enables them to maintain structural integrity through extreme weather and heavy usage.

Weathering the Elements

Deco bin blocks withstand temperatures from -40°C to +40°C without degradation. Their dense concrete structure resists frost damage, preventing cracking and spalling during freeze-thaw cycles.

The blocks feature water-resistant properties that protect against moisture penetration and chemical corrosion. This resistance helps maintain block stability in areas with high rainfall or snow accumulation.

Surface treatments and specialized concrete mixtures enhance their defence against UV radiation and acid rain. These protective measures extend service life in exposed outdoor settings.

Applications in Landscape and Construction

Deco bin blocks create sturdy retaining walls for soil retention and erosion control. Their interlocking design allows for quick assembly and disassembly in temporary construction projects.

Material storage yards utilize these blocks to separate different aggregates and prevent cross-contamination. The blocks’ substantial weight keeps them firmly in place without additional anchoring.

Common Applications:

- Salt and sand storage facilities

- Waste management centres

- Agricultural silage bunkers

- Construction site barriers

Optimizing for Energy Conservation and Insulation

The thermal mass of Deco bin blocks helps regulate temperature in storage facilities. Their dense composition slows heat transfer, reducing energy costs in climate-controlled environments.

Strategic placement of blocks creates wind barriers that protect sensitive materials and reduce heating requirements. This placement can decrease energy consumption by up to 15% in storage facilities.

The blocks’ configuration can be modified to incorporate additional insulation materials. This adaptability makes them suitable for both temporary and permanent structures requiring temperature control.

Conclusion

Deco bin blocks demonstrate exceptional resilience in challenging environmental conditions through their high-quality concrete composition and specialized manufacturing processes.

The combination of premium materials, strategic reinforcement, and proper installation techniques ensures these blocks maintain structural integrity despite exposure to extreme temperatures, moisture, and chemical agents.

Their proven track record in industrial, commercial, and infrastructure applications validates their reliability as a durable solution for long-term storage and containment needs.