The automotive industry stands as a testament to human ingenuity and the relentless pursuit of precision engineering. At the heart of this industry’s innovation is CNC machining, a technology that has revolutionized how components are manufactured, ensuring vehicles are not only more efficient but safer and more reliable than ever before.

This blog post dives into the indispensable role of CNC machining services in the automotive sector, highlighting how this technology is shaping the future of transportation. Plus, we’ll explore how CNC machining is driving innovation and growth in the industry while also addressing common misconceptions about its capabilities. Keep on reading to learn more!

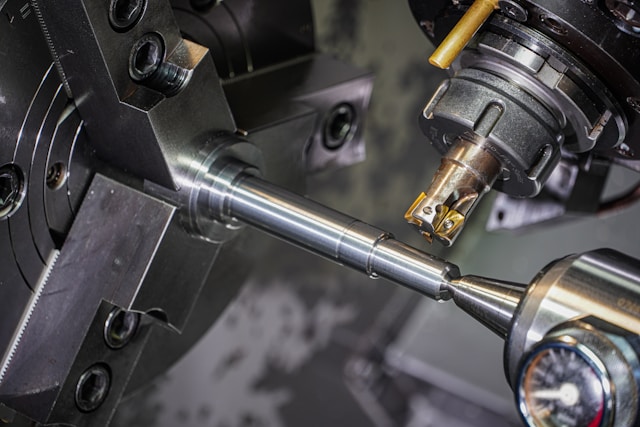

The Essence of CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. This process allows for the highly precise production of complex parts with minimal human intervention. CNC machining stands out for its ability to produce with high accuracy, repeatability, and speed, making it a cornerstone in the manufacturing of automotive components.

The Automotive Industry: An Overview

The automotive industry is a pillar of global economic stability and innovation, continually pushing the boundaries of technology, design, and manufacturing. It relies heavily on precision engineering to meet the stringent safety and performance standards required by regulators and expected by consumers. The sector’s evolution is marked by advancements in materials science, electronics, and manufacturing techniques, all converging to produce vehicles that are more durable, efficient, and environmentally friendly.

The Role of CNC Machining in Automotive

CNC machining services play a pivotal role in the automotive industry, from the development phase through to final production. Here are several key areas where CNC machining is indispensable:

- Prototyping: CNC machining allows engineers to rapidly produce and test prototypes, making it possible to explore new designs and innovations quickly.

- Component Manufacturing: Many critical vehicle components, such as engine parts, transmissions, and suspension systems, are produced using CNC machining. Its precision is crucial for components that must meet strict tolerances to function correctly.

- Customization and Aftermarket Parts: CNC machining also caters to the aftermarket sector, providing custom parts for vehicle enhancement and repair.

Moreover, to become a CNC machining expert, specialized training is necessary. As the automotive industry has become increasingly complex and competitive, CNC machinists must possess a wide range of skills, including programming, CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing), and a deep understanding of materials and their properties. And, on the CNC Machinist website, and other similar ones, you can read more about the qualifications and ways to enhance your skills in this field. Not only does this level of proficiency ensure high-quality parts, but it also improves efficiency, reducing production costs.

Advancements in CNC Technology

Recent developments in CNC technology have further expanded its applications in the automotive industry. Some of these advancements include:

- Increased Automation: Automated tool changers and workpiece positioning systems have reduced production times and improved efficiency.

- High-Speed Machining: Newer CNC machines can operate at higher speeds without compromising precision, significantly reducing turnaround times for parts manufacturing.

- Adaptive Machining: This technology allows machines to adjust cutting conditions in real time based on feedback from sensors, reducing errors and scrap rates.

Future of CNC in Automotive

The future of CNC machining in the automotive industry looks promising, with several trends poised to redefine its role further:

- Integration with Additive Manufacturing: Combining CNC machining with 3D printing opens up new possibilities for complex parts production, leveraging the strengths of both technologies.

- Smart CNC Machines: The integration of IoT (Internet of Things) technology into CNC machines is leading to smarter, more efficient production systems that can predict maintenance needs and optimize operations autonomously.

- Sustainability: Advances in CNC technology are also focusing on reducing waste and energy consumption, aligning with the automotive industry’s move towards sustainability.

CNC machining services are undeniably central to the automotive industry’s ongoing quest for innovation, efficiency, and precision. As technology evolves, so too will the capabilities of CNC machining, promising to deliver even more significant contributions to the automotive sector. The synergy between CNC machining and automotive manufacturing is a powerful driver of progress, pushing the boundaries of what’s possible in vehicle design and production.

The road ahead is exciting, and CNC machining will undoubtedly continue to play a vital role in shaping the future of the automotive industry. Even as we look towards new frontiers like electric and autonomous vehicles, CNC machining will remain at the heart of it all, powering this ever-evolving industry forward. So, if you have a passion for precision engineering and an eye for detail, consider joining this dynamic sector by exploring a career in CNC machining.