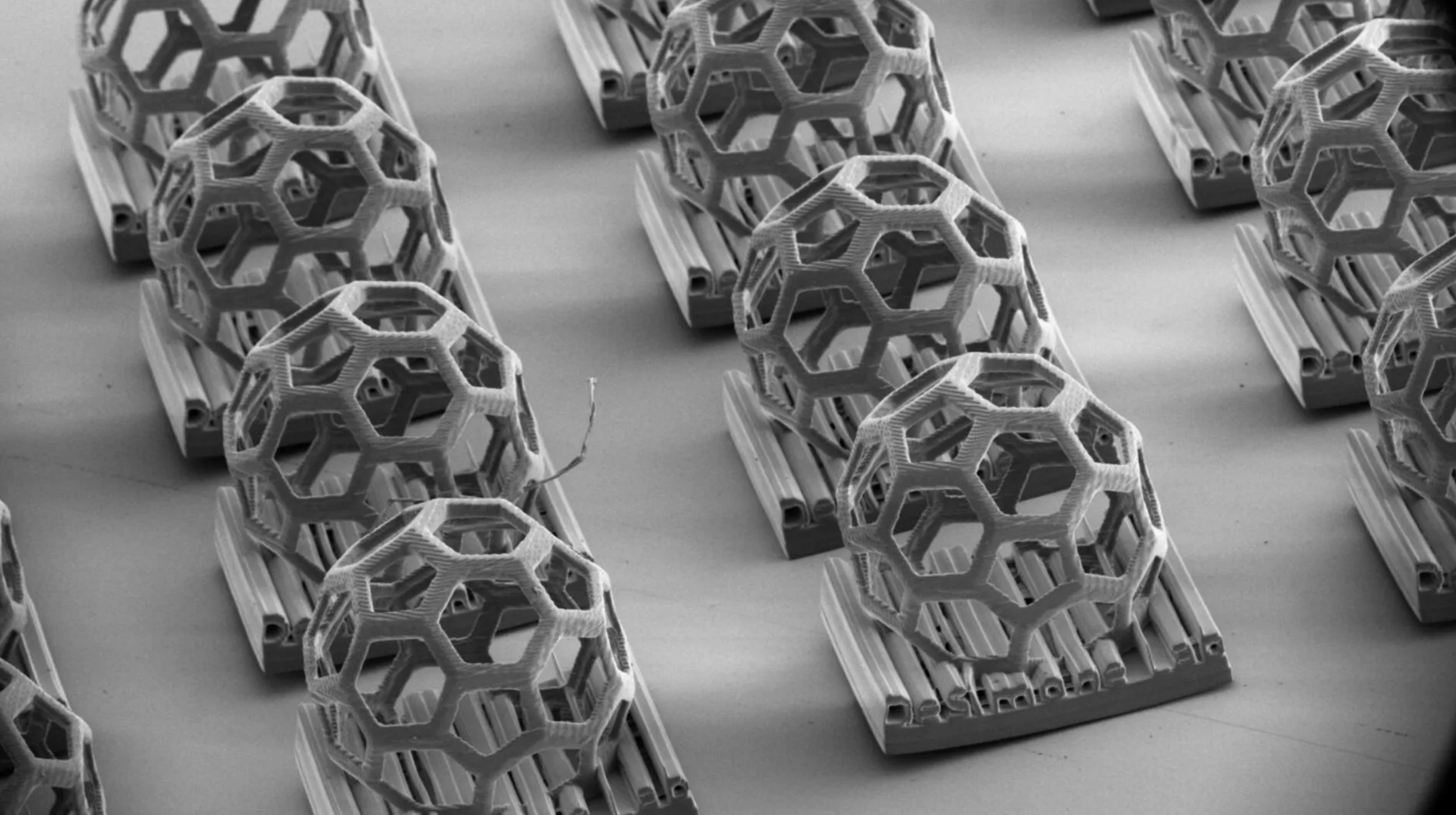

Stanford researchers have revolutionized 3D printing by achieving high-speed, microscale production using a technique called continuous liquid interface production (CLIP). Their novel CLIP method cranks out a million dust-sized particles daily, each boasting intricate details. This breakthrough by a research team led by Joseph DeSimone, a professor of Translational Medicine at Stanford, opens doors for mass-producing minuscule, custom-designed components.

Precision at Speed: Overcoming the Limits of Traditional 3D Printing

Previously, microscale 3D printing using traditional methods was a sluggish process, often requiring a trade-off between speed and precision. Stanford’s CLIP technique eliminates this obstacle, enabling the rapid creation of complex, microscopic objects with remarkable detail. This paves the way for exciting applications in diverse fields like medicine, manufacturing, and scientific research.

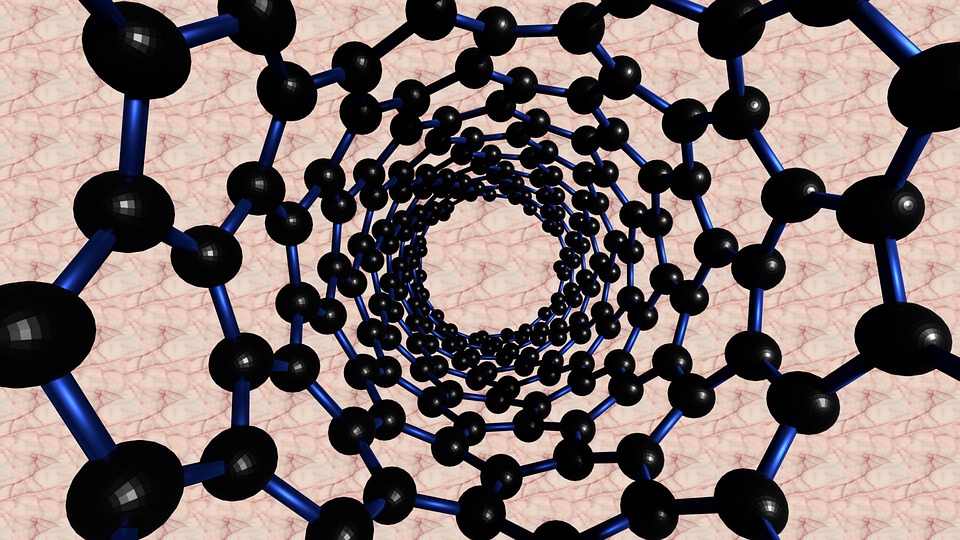

Imagine 3D-printed particles so tiny they resemble dust yet intricate enough for specialized purposes. This technology has the potential to revolutionize drug and vaccine delivery, creating microscopic carriers precisely designed for efficient medication transport within the body. It could also transform microelectronics, enabling the fabrication of ever-smaller, more powerful electronic components. Additionally, this innovation could hold immense value in microfluidics, a field that deals with manipulating fluids on a microscopic scale.

Stanford’s CLIP Method and the Future of Manufacturing

With Stanford’s groundbreaking CLIP method, the possibilities for creating and manipulating the microscopic world seem limitless. This advancement signifies a significant leap towards a future where intricate structures, invisible to the naked eye, can be mass-produced with remarkable precision and speed.

DeSimone said, “Using light to fabricate objects without molds opens up a whole new horizon in the particle world,”

“And we think doing it in a scalable manner leads to opportunities for using these particles to drive the industries of the future. We’re excited about where this can lead and where others can use these ideas to advance their own aspirations.”

The research findings were published in the journal Nature.