The Journey to Replicate Spider Silk

Scientists have achieved a significant breakthrough by successfully replicating the intricate molecular structure of spider silk. They have developed an artificial spider gland capable of spinning silk virtually indistinguishable from its natural counterpart. This breakthrough holds immense promise for revolutionizing countless sectors, from textiles and medicine to aerospace and construction.

For centuries, scientists have been captivated by the extraordinary properties of spider silk. Its unparalleled strength, exceeding steel’s pound-for-pound tensile strength, coupled with remarkable elasticity, has ignited awe and fueled relentless attempts at replication. However, the intricate biological processes governing its production presented a formidable hurdle.

Surpassing Nature: The Superiority of Artificial Silk

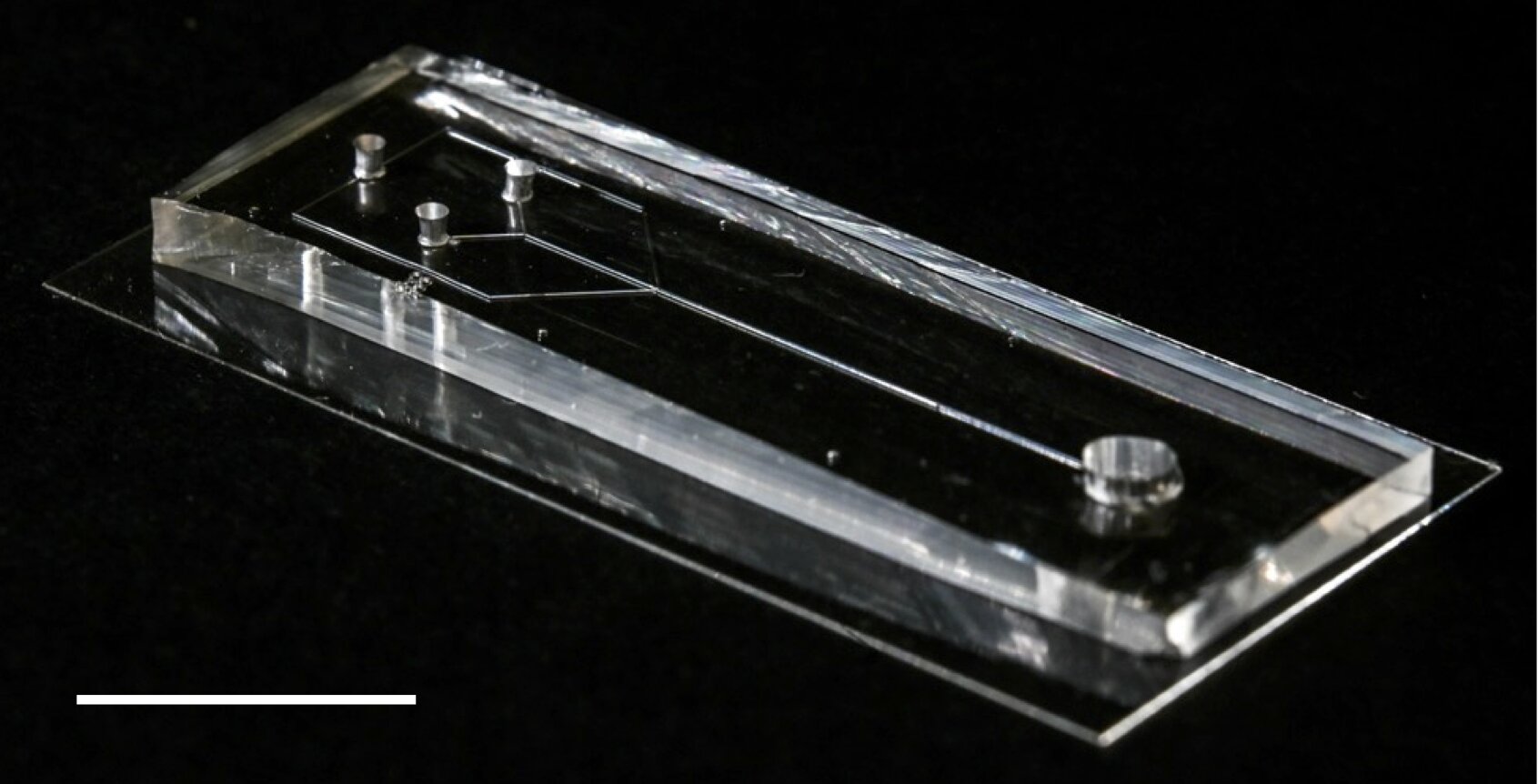

The revolutionary artificial spider gland, conceived by Keiji Numata’s team at the RIKEN Center for Sustainable Resource Science in Japan, ingeniously sidesteps this hurdle by meticulously mimicking the natural silk-spinning process.

The artificial silk spun by this groundbreaking gland outperforms natural silk in strength, flexibility, and biocompatibility. With versatile applications, its production process is not only more sustainable but also more scalable compared to traditional methods relying on silkworm cocoons.

BeyondGarments: Artificial Silk’s Impact on Medicine, Aerospace, and Construction

The groundbreaking artificial silk holds transformative potential across various industries. It can revolutionize textiles, creating high-performance garments. In the medical field, it enables biocompatible implants and sutures, promoting seamless integration and healing. The material also shows promise in aerospace and construction, introducing lightweight yet durable materials. Moreover, it has the potential to shape regenerative medicine by enabling the creation of artificial organs and tissues, providing hope for countless individuals.