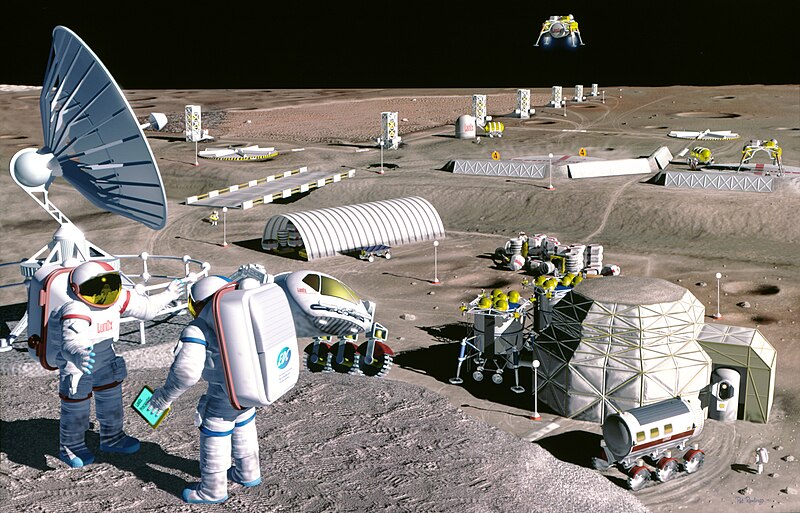

As we venture further into space, keeping long-term missions sustainable becomes a bigger challenge. Extended space missions demand on-site production of essential materials and equipment.

But, thanks to 3D printing, we can revolutionize space colonization

3D printing allows us to make tools and structures quickly and easily without the need for large factories. Plus, it’s more eco-friendly and reduces the space and weight needed for materials. This technology can be crucial for creating self-sustaining and customizable space colonies.

However, this emerging technology presents several challenges for manufacturing and construction in space, and scientists are actively exploring how it could be adapted for use on other celestial bodies.

Overcoming Challenges in Space Manufacturing

West Virginia University researchers conducted experiments with titania foam to understand 3D printing in microgravity. They emphasize that the Moon’s mineral resources, like titanium dioxide, can be used sustainably, reducing the need for costly Earth-to-space material transport for lunar missions.

The study revealed that titanium dioxide foam behaves differently in microgravity compared to Earth’s gravity. To facilitate microgravity experiments, the team has developed a dedicated 3D printer.

Titania foam was chosen for its potential to shield astronauts from UV radiation on the Moon. Additionally, it showed photocatalytic properties that could aid in air and water purification using light.

The team plans to send their 3D printer on a six-month mission to the International Space Station (ISS) to closely study the printing process.