Traditional methods of 3D-printing metal objects involve the application of heat. However, this poses limitations when it comes to producing heat-sensitive electronics and similar items. A recent breakthrough introduces a gel that enables printing such objects at room temperature.

This innovative solution offers a promising alternative for manufacturing these delicate components.

Developed by the researchers from North Carolina State University, this marks the first instance of printing a metallic 3D object under such conditions. In their study published in the journal Matter, the scientists describe the process of creating the gel.

To create the metallic gel, the researchers used a solution consisting of micron-scale copper particles in water. Eutectic gallium indium alloy (EGaIn) microparticles and hydrochloric acid are then added.

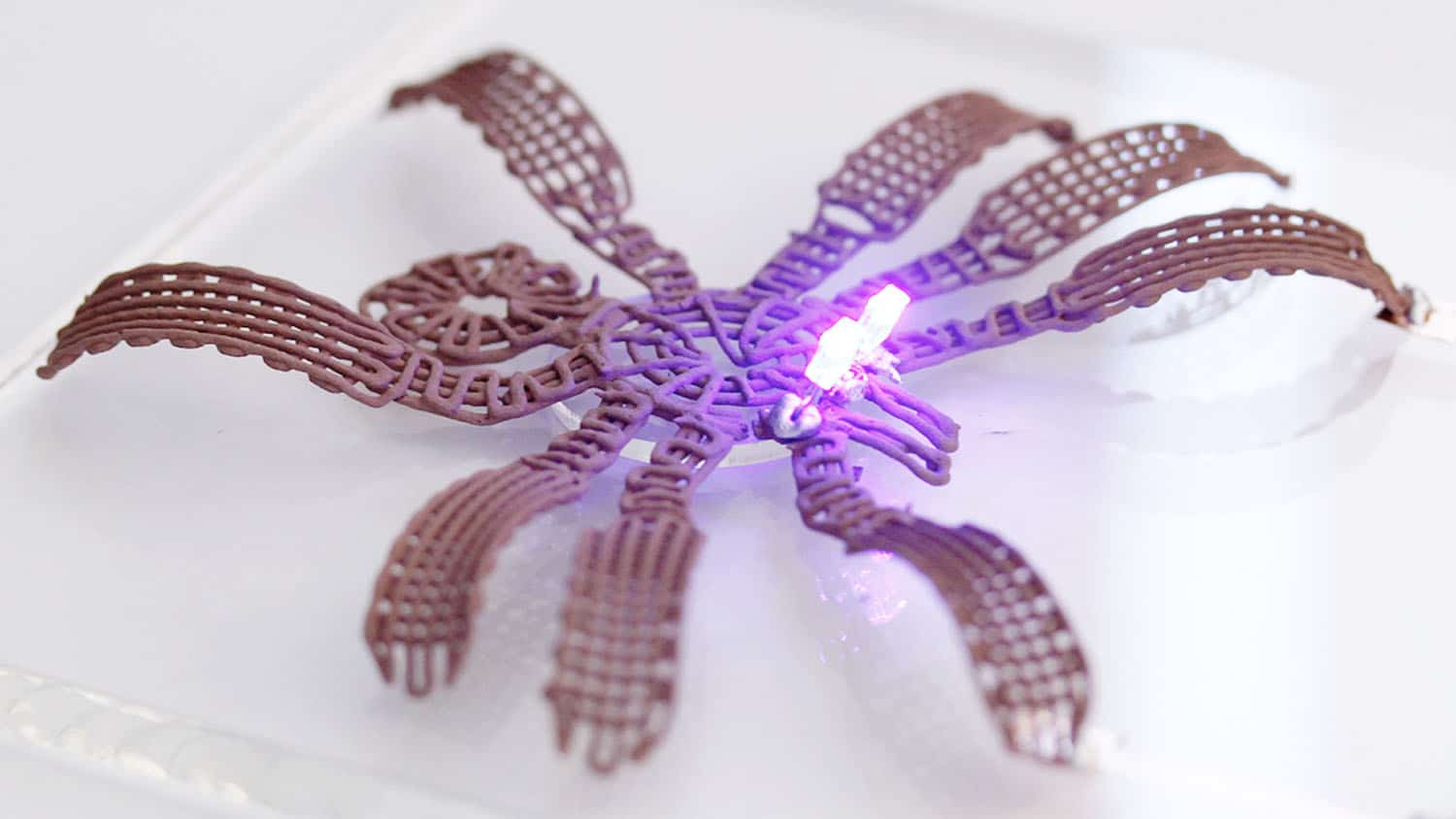

The end result is a rigid, highly conductive three-dimensional object, with up to 97.5% metal content and the remaining portion composed of methylcellulose.

“This gel-like consistency is important because it means you have a fairly uniform distribution of copper particles throughout the material,” Michael Dickey, co-corresponding author of a paper, said in a media statement. “This does two things. First, it means the network of particles connects to form electrical pathways. And second, it means that the copper particles aren’t settling out of solution and clogging the printer.”

The metallic gel, once printed, maintains its shape without deformation. The gel can be efficiently produced by utilizing a standard 3D printing nozzle. This type of nozzle precisely deposits the gel material layer by layer, allowing for the construction of the desired object.