As concerns over climate change increase, companies are becoming more sustainable and greener. Sustainable manufacturing has many benefits; besides helping the environment, it also modernizes businesses.

Customers are now searching for sustainable products and services to ensure they commit to sustainability and adopt great initiatives and policies. Eco-friendly processes and efficient practices are at the forefront of marketing strategies and social responsibility. Fortunately, there are a number of ways industrial plants can reduce carbon footprints, adopt eco-friendly practices and become more sustainable. Here are four strategies you can adopt to achieve green manufacturing.

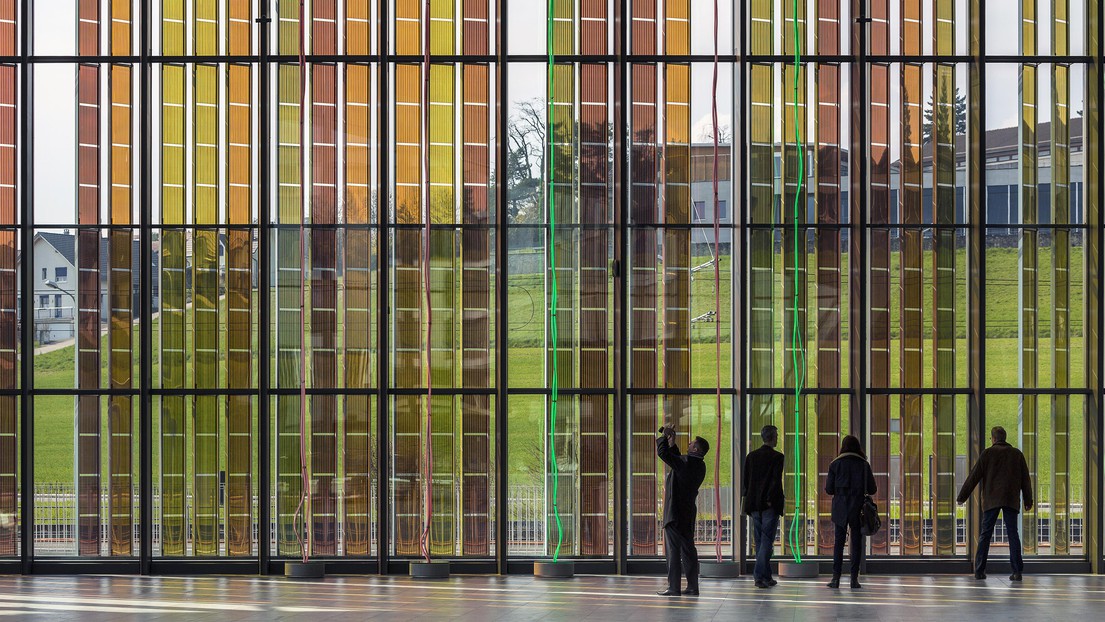

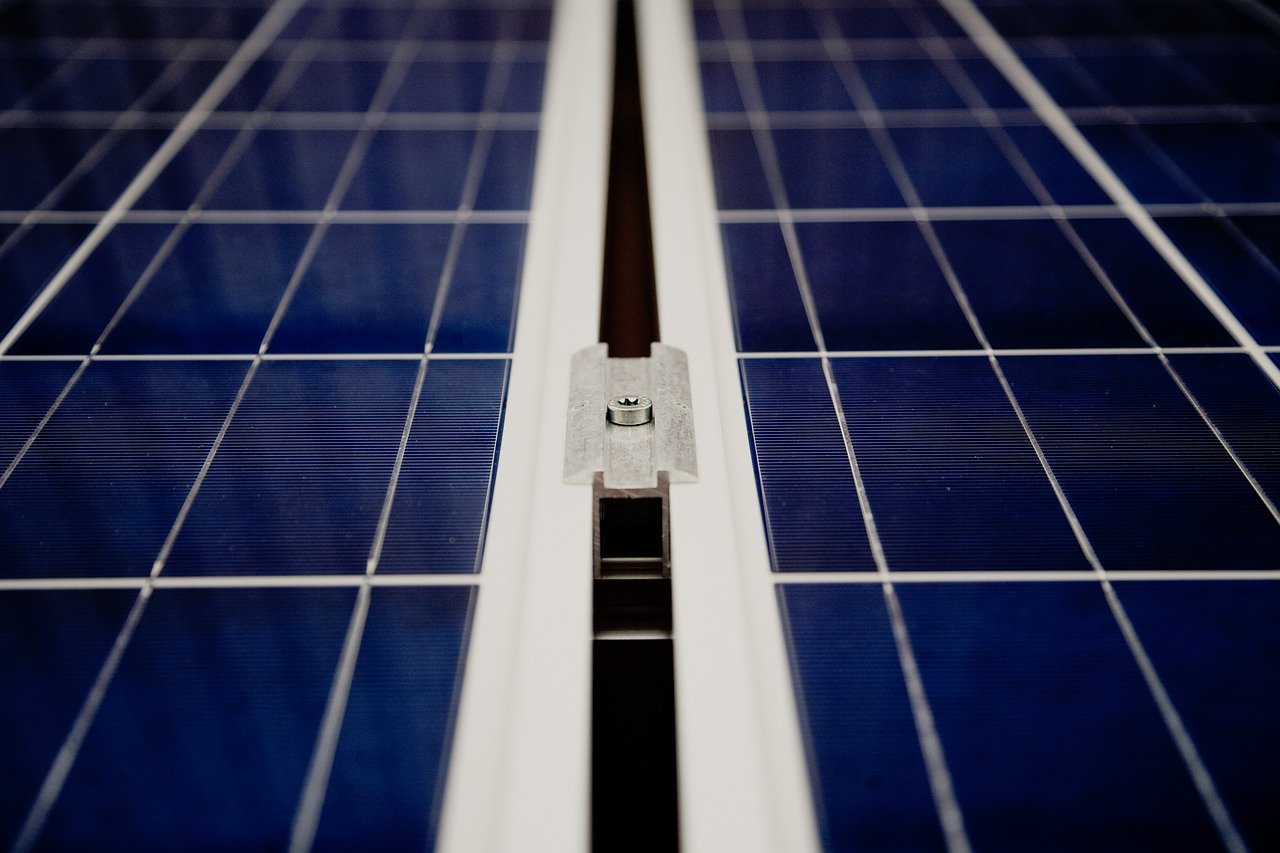

1. Switch to renewable energy

Leveraging renewable energy can help industrial plants create a sustainable workplace and contribute to a healthier environment. Renewable energy is expected to be the main global power source by 2035, according to the 2019 Clean Jobs America report. Green power sources such as solar panels, wind, rain, biomass, and geothermal heat are also more cost-effective than conventional fossil fuel energy sources since they use natural resources.

Chariot Energy can make your plant a true consumer of clean, green power. You can also benefit from tax incentives and earn your money back depending on your state or support renewable energy by choosing a renewable electricity tariff with your supplier.

2. Reduce, reuse, and recycle waste

Obtaining and processing raw materials is the greatest contributor to waste in manufacturing plants. Reduce waste by looking for more sustainable sources of supplies. For instance, you can broaden the use of cassava starch for manufacturing a form of plastic instead of using fossil fuels. Another great way to reduce waste is to recycle products rather than using raw materials. You can reuse excess products from your manufacturing plant or buy fabric from a supplier that uses recycled items, such as plastics.

3. Audit energy use

Manufacturing industries usually use vast amounts of electricity and gas. Adopting energy-efficient practices can considerably help reduce the plant’s energy use costs. Begin by conducting an energy audit, ideally during your next scheduled plant downtime, to identify areas that require improvements.

HVAC systems are particularly huge energy and money drainers. Therefore, change filters and insulation to prevent hot and cold air from escaping. You can also automate temperature controls with a programmable digital thermostat.

Switch out standard industry lighting, such as incandescent bulbs, for LED lights, which use less energy and last 25 times longer. Monitor your eco-friendly adjustments and energy use to ensure you are operating at optimum efficiency.

4. Digitize in-house communication

Making all your in-house communication 100% digital can help you save tons of paper each year while making your overall operations more efficient. Mobile communication is increasingly becoming a popular way to enable frontline manufacturing employees to improve operations in real-time.

A digitally connected workforce is faster, more productive, safer, and eco-friendly. The mobile-first communication tools also allow workers to partner with their managers, peers, and even machines. This may also rebrand a manufacturing plant into a green, tech-advance facility that attracts the attention of millennials inside the workforce.

Endnote

Making your industrial plant eco-friendly isn’t an overnight job. It takes time and effort to make positive and permanent changes. Fortunately, these tips can help you make your plant a safer workplace and a green manufacturing environment. Partnering with other companies going green can also help ease your burden.