A skin graft is a complicated procedure that carries a high risk of complications like chronic pain, abnormal pigmentation, and infections.

Bioengineered skin holds great promise for humans and burns victims, but it has so far only been produced in flat sheets

These flat skin sheets don’t work well for the complex body part with corners and edges like the hands. To overcome these challenges, a team of researchers from Columbia University has developed a more accommodating alternative in 3D form.

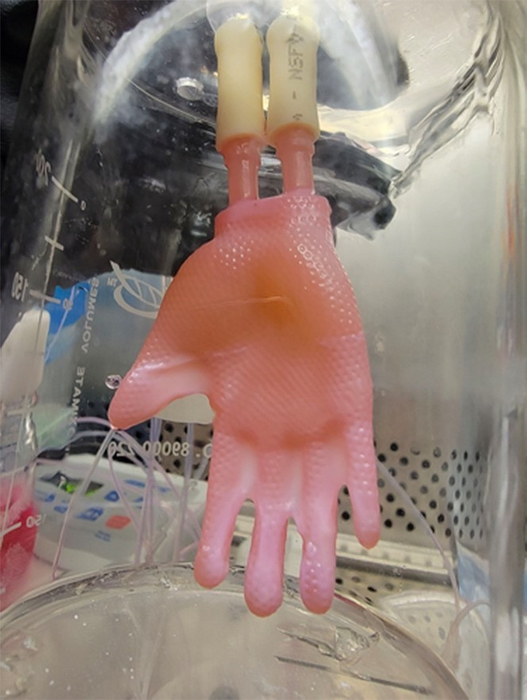

The process of growing engineered skin in complex, three-dimensional shapes begins with a 3D laser scan of the target structure, such as a human hand.

This scan is used to 3D print the hollow model of the exterior of the targeted body part. The model is then seeded with fibroblast cells, which generate the skin’s connective tissue, and essential collagen proteins to give the skin its structure.

After 14 days, a suspension of keratinocytes (cells that make up most of the outer layer of skin) is added, and the cells are allowed to attach and grow. The inside of the model is perfused with growth media, which support and nourish the developing graft.

Once these cells grow into real skin, the bioengineered skin is removed from the model into 3D shapes that can be slipped over the body like a garment.

3D human skin cell grafts have been successfully applied to the hind legs of mice in laboratory tests. The skin grafts were fully integrated into the surrounding mouse skin within four weeks. However, more research is needed before human trials can take place.