Colonizing the Moon may still be a far-away concept but that doesn’t stop space agencies from preparing for it.

Recently, European Space Agency (ESA) partnered with Incus, OHB System AG, and Lithoz GmbH for developing and testing 3D printing in a micro-gravity environment. Researchers want to check whether this technology would help them create materials in the lunar base using existing surface materials. Their main focus is to resolve the issues regarding future lunar settlements.

The project is of great significance as it could address problems related to supply chains and acquiring supplies from Earth

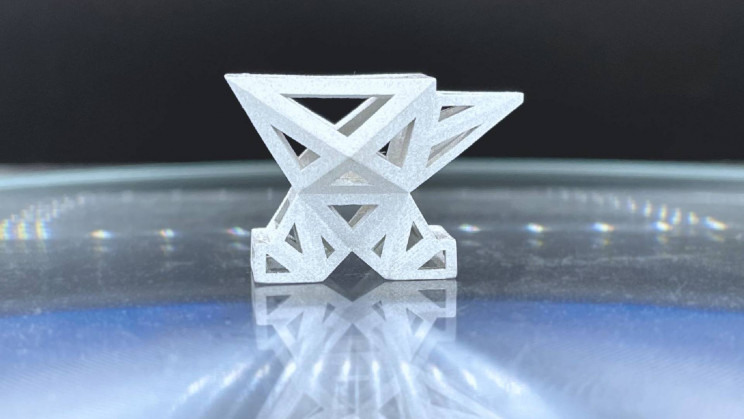

Incus’ lithography-based metal manufacturing (LMM) process involves 3D printing technology for producing advanced metal parts using the principle of photopolymerization. For creating new materials, this innovative technology uses recycled powders from scrap metals that are readily available on the Moon.

“Lithographic techniques such as those developed by Incus and Lithoz enable the combination of high-precision 3D printing with high-performance metals and ceramics while remaining extremely resource-efficient. While these concepts have been successfully demonstrated on Earth, the activities of such projects are critical to fill technological gaps and enable additive manufacturing to be implemented in a space environment, ”said Dr. Martin Schwentenwein, Head of Material Development at Lithoz.

With this project, researchers plan to process scrap metals available on the Moon’s surface to produce a high-quality final product. If successful, future missions on the moon will not completely depend on Earth for everything they need.