For years now, the lithium-sulfur (Li-S) battery is considered the most likely successor to the highly successful lithium-ion cells. Li-S feature higher energy densities (double that of Li-ion), reduced cost for sourcing the materials and can be recharged for many hundreds of times.

However, it is not all perfect with the Li-S batteries. Sulfur has a problematically low electrical conductivity, has large volume expansion rates, and the inevitable leakages shorter the life cycle of the battery.

Now, researchers from Singapore’s NanoBio Lab have designed a new type of a lithium-sulfur cathode that is less complex than the existing iterations.

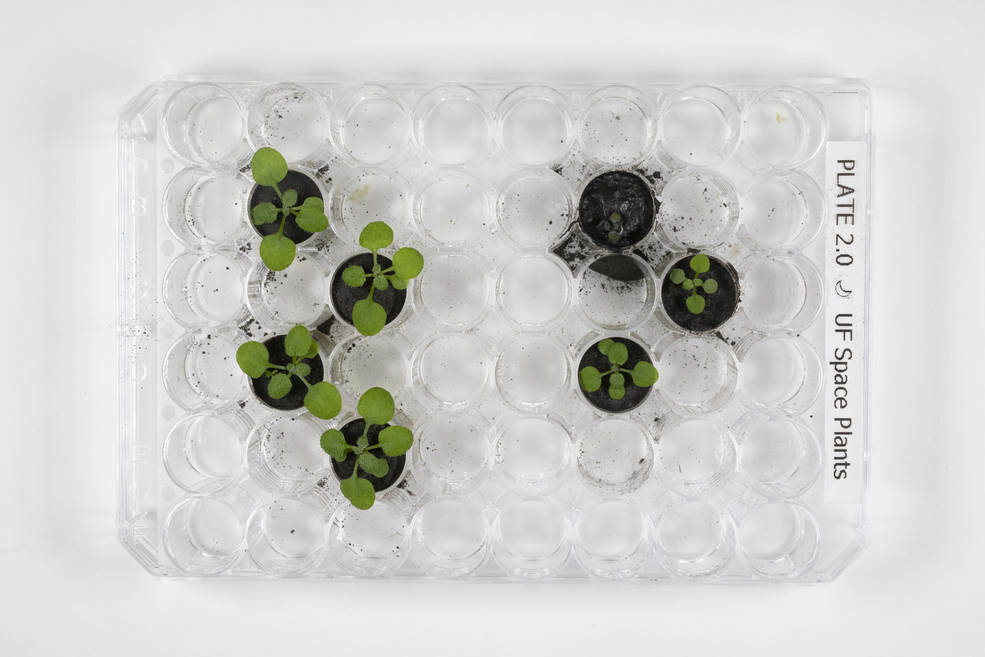

Illustration of NBL’s method of preparing sulfur cathode (top) and how it is conventionally prepared (bottom). Image Credit: NanoBio Lab (NBL) and A*STAR

Having to produce something simpler in design translated in lower production costs, shorter production times, and a lot better feasibility potential. The researchers have built the cathode in two steps, with the formation of the carbon host followed by the addition of the sulfur source.

What this does is to minimize the chances of the carbon scaffold to collapse during charging, which was one of the previous design’s inherent severe problems. Moreover, the two-step process creates a porous nanomaterial where the sulfur may roost in, eliminating it’s low conductivity and high expansion rate problems.

The new cathode increased the specific capacity by 48%, and decreased the capacity fade by 26%. In numbers, this was 4mAh per cm2, and 1220mAh/g.

The team tested the new cathode design over 200 charging cycles, and recorded only a minimal loss in performance. This means that the new design has all the potential to enter actual production, and we may soon start seeing Li-S cell powering our gadgets, or even our electric cars.

After all, the demonstrated production method is industrially scalable, so there’s no reason why we shouldn’t get to the next step in battery technology.

The NBL research team (from right to left): Prof. Jackie Y. Ying, Mr. Jian Liang Cheong and Dr. Ayman AbdelHamid.