It is hard to imagine any industry that hasn’t been profoundly affected by robotics. Since the early 1960s, the manufacturing industry has made use of industrial robots. And areas such as medicine, mining, as well as police work and military operations, have been transformed by robotics. Now, the benefits of industrial robots that have long been a part of the normal operating procedure of major corporations are available to everyone in the form of low cost robotics.

Automation has become a necessary part of the production processes of nearly every industry. Low cost robotics provides an uninterrupted and continuous work system, and can help to give small and medium-sized businesses a competitive edge.

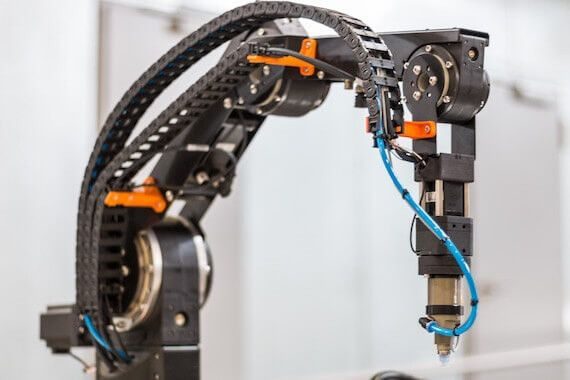

The company’s aim is to create customized solutions to fit nearly any type of manufacturing process.

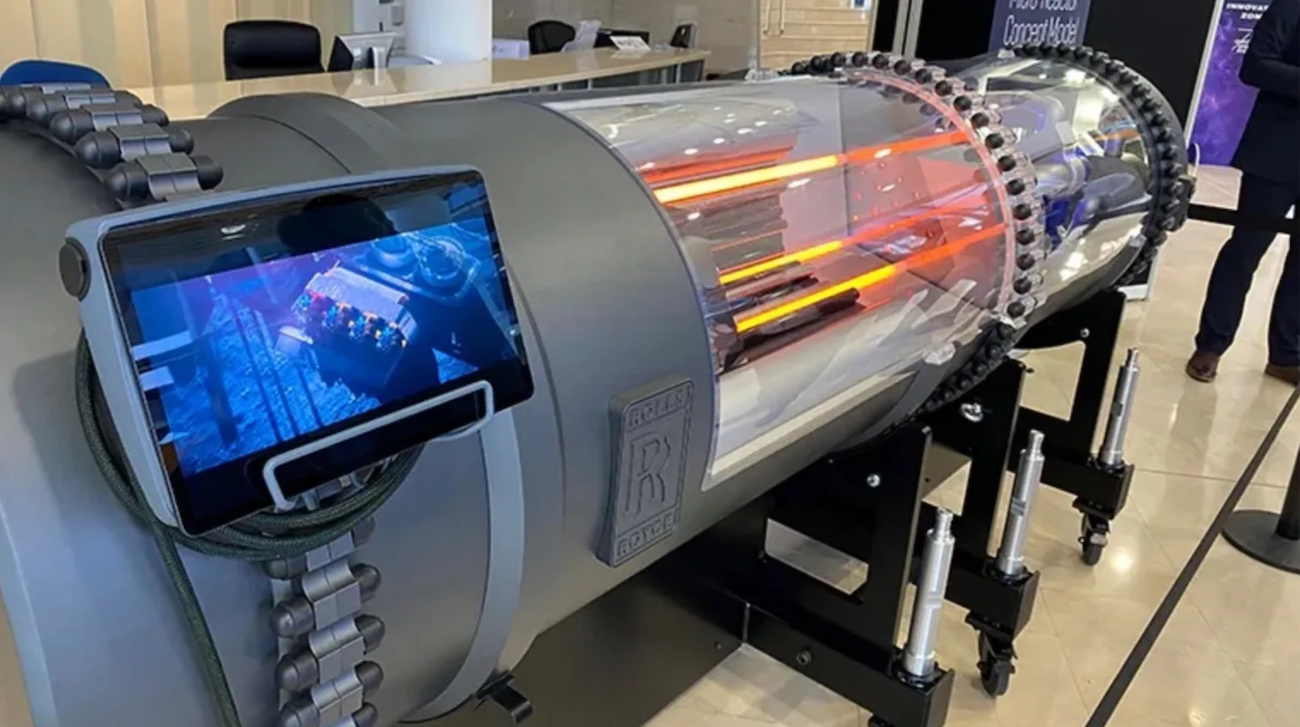

We thought that this system (seen in the video below), developed by EPS GmbH using igus’ robolink® components, to automatically scan and digitize books was a particularly fascinating application of the technology.

If you would like to learn more about the affordability and flexibility of low cost robotics, there is a free ebook by Dr. Ing. Sebastian Feldmann, a member of the Faculty of Engineering at the University of Duisburg-Essen, that discusses the possibilities. You can order the book by visiting this link.

And, if you have any big ideas about how to integrate low cost robotics into manufacturing processes, you might want to check out igus’ Innovation Competition. The winner will get a robolink® articulated arm or $3,000 worth of robolink® components.

Image courtesy igus