To ensure non-oxidized, zero color welds are achieved when welding metals such as stainless, duplex and chrome steels, titanium and nickel alloys, a Weld Purge Monitor® (oxygen monitor) must be used to measure the oxygen level before and during welding.

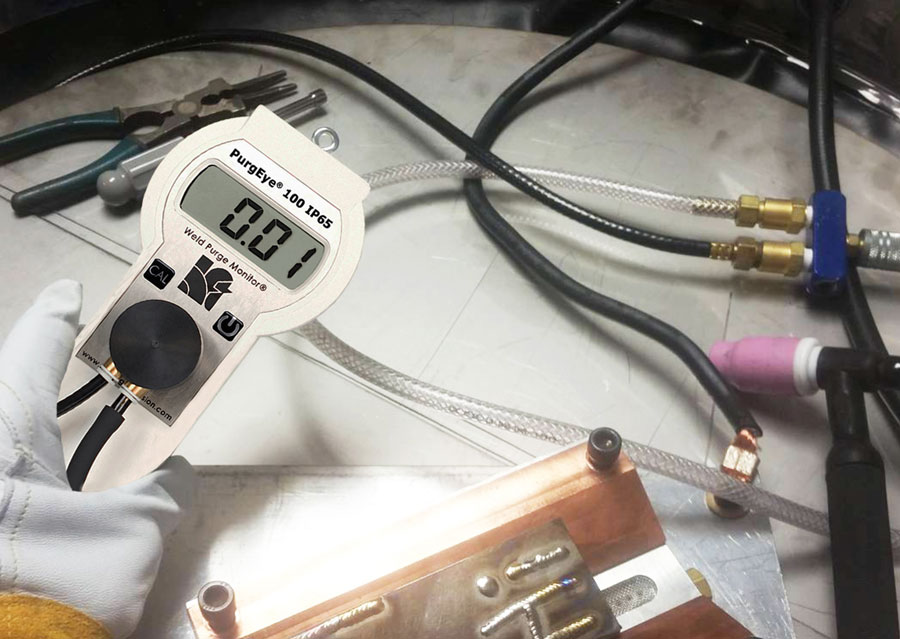

The World Standard PurgEye® 100 IP65 Weld Purge Monitor® designed and manufactured by Weld Purging Experts Huntingdon Fusion Techniques HFT® is available at a low cost, avoiding the requirements to fill entire tubes and pipes with expensive inert gas and avoiding the need to guess when the oxygen level is low enough to begin welding.

A customer in the UK recently said: “When working with medium to large diameter exotic pipework, using the PurgEye® 100 can prevent you from having a very bad day! Previously, I only ever used the older model and the introduction of the PurgEye® 100 was a godsend. Anyone, from the welder who has had to carry out weld repairs due to root weld oxidization (or coking) on such materials, to the directors facing an expensive bill for re-work and possible tarnished company reputation, to the client with their project now running behind schedule, will know exactly what I mean. Weld Purge Monitors® are a necessity.”

The PurgEye® 100 is IP65 rated and comes with leak-tight push buttons, auto calibration features, vacuum-sealed leak-tight probe assembly, wrist/neck strap and tripod mount.

The extra long life sensor provides approximately 18 months life before it requires changing. A low sensor indicator will appear on the screen, warning that a new sensor is required. Once that icon appears, it provides the user with adequate time to obtain a new sensor, which can be fitted like changing a battery and the monitor can be re-calibrated easily by the user.

The PurgEye® 100 has a clear, easy to read LCD screen, with a 24 mm high display. The display also shows a low battery icon. When the monitor is not in use, an automatic sleep mode activates to conserve battery life.

The Weld Purge Monitor® was invented by HFT® in the 1970s and with over 40 years of innovation, design and manufacturing experience, the company now has a Family of PurgEye® Weld Purge Monitors® to measure oxygen levels from atmospheric content (20.94%) down to 1 ppm (accurate to 10 ppm).

Ron Sewell, Chairman for HFT® said: “All of Huntingdon Fusion Techniques HFT®’s Weld Purge Monitors® and Inflatable Tube, Pipe and Pipeline Weld Purging Systems are manufactured in the UK. We do not sacrifice on quality. We guarantee to help you achieve zero color welds, time and time again.”

View the PurgEye® 100 video below: