Haydale Composite Solutions (HCS) have been awarded a contract extension by UK utility company National Grid to develop 14 different lightweight composite Gas Transition Piece (GTP) solutions for 7 different pipeline diameters from 300-1050mm. Each size has a variant for use on sites where access to the pipe is restricted by space constraints.

Seals are used to prevent water ingress at ‘transitions’ where gas transmission pipes pass through concrete walled inspection pits. Over time, these seals may deteriorate, allowing water containing particulates such as sand and grit to abrade the surface of the pipe, causing damage. Regular inspections are therefore required at these transitions, which currently necessitate high risk and costly works to allow access to the pipe.

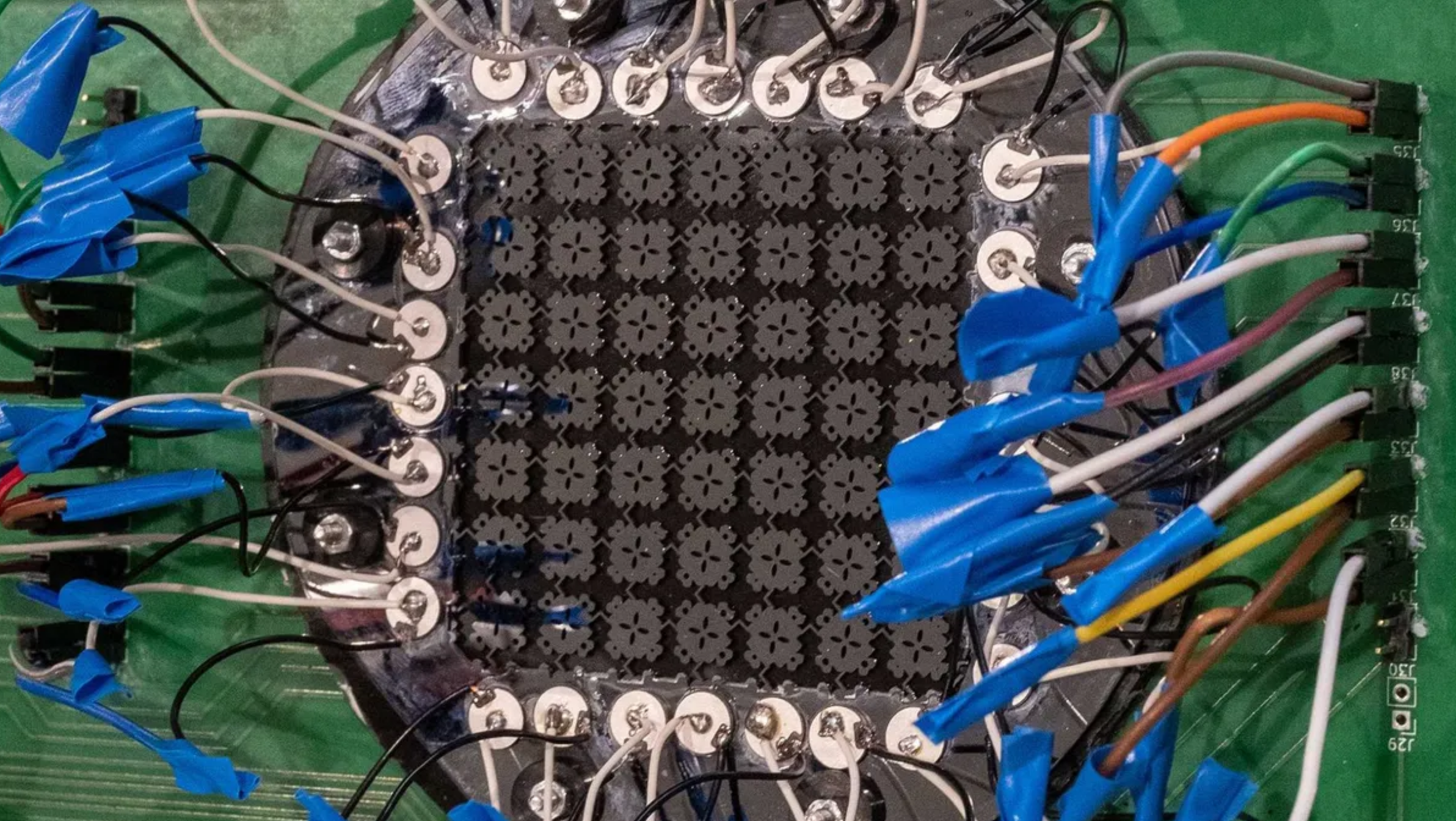

HCS developed a revolutionary composite gas transition seal for National Grid that allows technicians to quickly remove it, easily find out if there are any corrosion issues or damage, and then put it all back in a relatively simple operation. Working closely in conjunction with the National Grid R&D department, the HCS solution was to excavate an annulus in the concrete wall around the gas transmission pipe and insert composite GTP mouldings to provide an environmental seal around the gas pipeline. After installation, the composite GTP mouldings can be readily removed, without the need for heavy lifting equipment, extensive excavation work and hydro demolition to cut through the concrete walls. The novel GTP mouldings enable engineers to carry out rapid inspections of the pipeline with considerable savings in their time and costs.

Reflecting on the GTP development – Nick Weatherby of HCS commented, “We have been working with infrastructure for 25 years and the GTP construction builds on that experience. We designed the GTP to split into a series of segments for ease of handling in terms of size and mass. The sealing system houses hydrophilic seals that swell up to 400% in volume when wet, thereby sealing the transition and preventing ingress of water, sand or debris that might cause abrasion. On installation, the seals are in the dry state which provides significant clearance so the GTP can be easily installed. To remove with the seals expanded, the GTP comes complete with a series of Jacking pins that eases out the component for inspection.” He added, “As the GTP dramatically reduces the risk of damaging a large transmission pipe containing high-pressure gas and removes the need for subsequent excavation required after the initial installation, it offers huge savings on time and cost for pipe inspection.”

HCS has completed a series of R&D contracts with National Grid to develop the solution for 900 mm diameter pipelines which have been installed in 2 sites in the UK as proof of concept. HCS has filed a patent and registered the GTP design concept in the UK, Europe and North America. Following this, National Grid recently awarded HCS a follow-on contract to develop 14 different GTP solutions for 7 different pipeline diameters from 300-1050mm and for two clearance variants. This will enable the GTP solution to be rolled out across the entire gas transmission network in the UK. National Grid has identified the need for a total of approximately 300 units in the UK. Work on the contract is likely to span the next 15 months or so.

National Grid’s Project Manager, Paul Ogden commented, “During the next 6 years, up to 60 of these units are likely to be installed in the National Transmission System and that will significantly improve safety as well as creating savings of up to £5m in the next five to ten years, with further savings beyond that.”

Gerry Boyce, Managing Director of HCS said, “This is a demonstration of the traditional HCS composite business and I am delighted to win this follow on contract. We look forward to entering into discussions with National Grid on the scaling up and initial production of GTP units for installation in the grid and to working with the National Grid on the licencing of the technology in the UK, Europe and North America.”