I remember my 8th-grade shop class and the man who taught us how to weld. I made a metal log holder with two rings, a metal sheet and a couple of metal legs that required about 5 to 10 welds. My creation sat beside our fireplace filled with wood for years. I remember holding the welding equipment in my hands, a helmet with eye protection, and clothing to protect my skin. Being alone in the welding area was fun and strangely satisfying.

Human welding will soon, mostly, be going the way of the horse-drawn wagon. In the US, the total labor costs for manual welding are now $10 billion a year and new robotic welders can significantly decrease these costs.

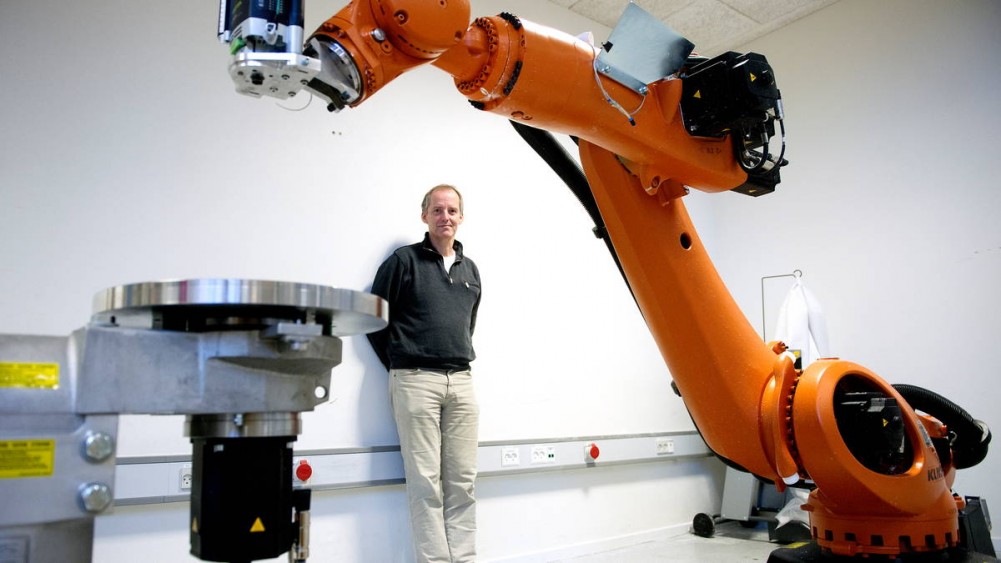

CorePath Robotics

A company known as CorePath Robotics, founded in 2015, is a joint venture between Science Ventures Denmark and Syddansk Teknolgisk Innovation, also from Denmark. CorePath is now offering, especially for small and medium-sized enterprises or SMEs, cost-effective automated welding, milling, and plasma cutting machines that can be quickly reprogrammed and do not depend on any external experts. The machines perform these tasks as well as post-processing which can be carried out with programmed CAD/CAM systems, manually, or with cheap robots. The company’s solutions offer:

- very fast online programming

- tight tolerances

- high quality

- high uniformity and output

- ability to remove the need for expensive subcontractors/experts

While CorePath will likely put thousands of welders out of a job, they are hiring like mad: engineers, designers, and business professionals alike. The company took part in the RoboBusiness 2015 show in San Jose California.