King’s Hawaiian (King’s) bread is nearly as well known as the Hawaiian Lei. For over 50 years, the company has been baking rounded lobes of sweet bread served up to tourists and purchased for friends and relatives back on the mainland.

The company’s first two large facilities, 30,000 sq. ft. and 40,000 sq. ft., were built in Southern California. In 2004, King’s built a 150,000 sq. ft. automated baking facility and headquarters nearby. Finally, in 2010, after reaching full capacity at all three facilities, and due to demand spreading across the United States, Kings chose to build a highly automated 125,000 sq. ft. facility in Oakwood, Georgia.

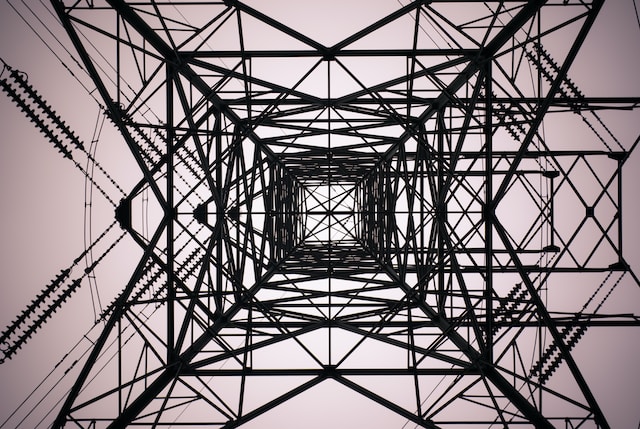

Common Network, Integrated Architecture, Integration and Data Sharing

Baking 8,000 pounds of bread an hour requires eleven specialized machines. These machines were manufactured by different Original Equipment Manufacturers (OEM) and required a control and information platform specifically designed for the bread baking environment that allow for multiple user interfaces and vendor support.

Advanced Data Collection Key to System

King’s was looking for a system that would completely automate the baking process and provide real-time information to management 3,500 miles away in California. The entire process of making bread from measurement to mixing ingredients to shaping of dough balls was just the beginning of the processes that needed to be centrally controlled and monitored. Additional machines allow the bread to rise, cool, be packaged, inspected and shipped.

With eleven machines involved in the process, OEMs were given clear common specifications about how the architecture and integration of the machines would be accomplished.

Finally, the automated system was set up so that local management would have 100% control over daily production with the ability to make changes and troubleshoot problems in real time.

Owners Are Happy

The project, which was completed in October 2011, a week earlier than planned, has doubled Kings’ production of bread. The plant was built so another line could be added in the future.

According to King’s management:

“The common network architecture enabled us to get this plant up and operational in a matter of weeks instead of months,” Williams said. “And through the continuity of materials, we’re able to stock spare parts we’re familiar with, reducing lost production time during a failure. This plant gives King’s Hawaiian the capacity we need for the foreseeable future.”

Related articles on IndustryTap:

- Process Automation: Monitoring “Health” Of Iron Ore Plant

- Step Right Up! Next Week’s Industrial Automation Electronics Conference to Focus on Issues and Opportunities in $75 Billion Market

- Automation is Changing Every Component of the Modern Farm

References and related content: