Industrial organizations are facing unprecedented challenges, in part due to the current unstable economic conditions, as well as competition from disruptive startups. The recent pandemic has also placed a bigger burden on manufacturers. It’s forced them to rethink risk and contingency plans, workplace safety, and the importance of managing remote teams.

The move towards digital transformation has accelerated, too, with the manufacturing industry being forced to innovate in order to maintain continuity of operations post-crisis.

Innovative technologies including the IoT and AI are offering unprecedented possibilities for change, while manufacturing capabilities look set to be greatly accelerated with the rise of 5G over the forthcoming years.

However, enthusiasm for, and investment in, all things digital is not enough to guarantee results, and some companies are investing too much too soon. The key to success when it comes to digital transformation is to align a digital transformation strategy with the organization’s broader needs and goals.

Here are some of the key transformation trends on a manufacturer’s radar:

1. Industry 4.0

Industry 4.0 is a trend that blends manufacturing, industrial, and digital. It’s also termed ‘the fourth industrial revolution’. The main aim of Industry 4.0 is to automate all production processes in real time. For example, the implementation of machines with sensors that can interact with other machines and exchange data without the need for a human operator.

In future, Industry 4.0 will blur the lines of actual and virtual warehouses, freeing up manpower whilst enabling more efficient collaboration.

2. IoT

IoT or ‘the internet of things’ is part of Industry 4.0, and represents the billions of devices that are connected via the internet, all collecting and sharing data. Examples are the ‘soft’ phones used in contact centre solutions or ‘smart thermostats’ and lightbulbs that can be switched on via a smartphone.

In manufacturing, the IoT often refers to M2M or machine-to machine. IoT systems are also the foundations of the modern day manufacturer’s supply chain. For example, in the way they can work in tandem with inventory management software.

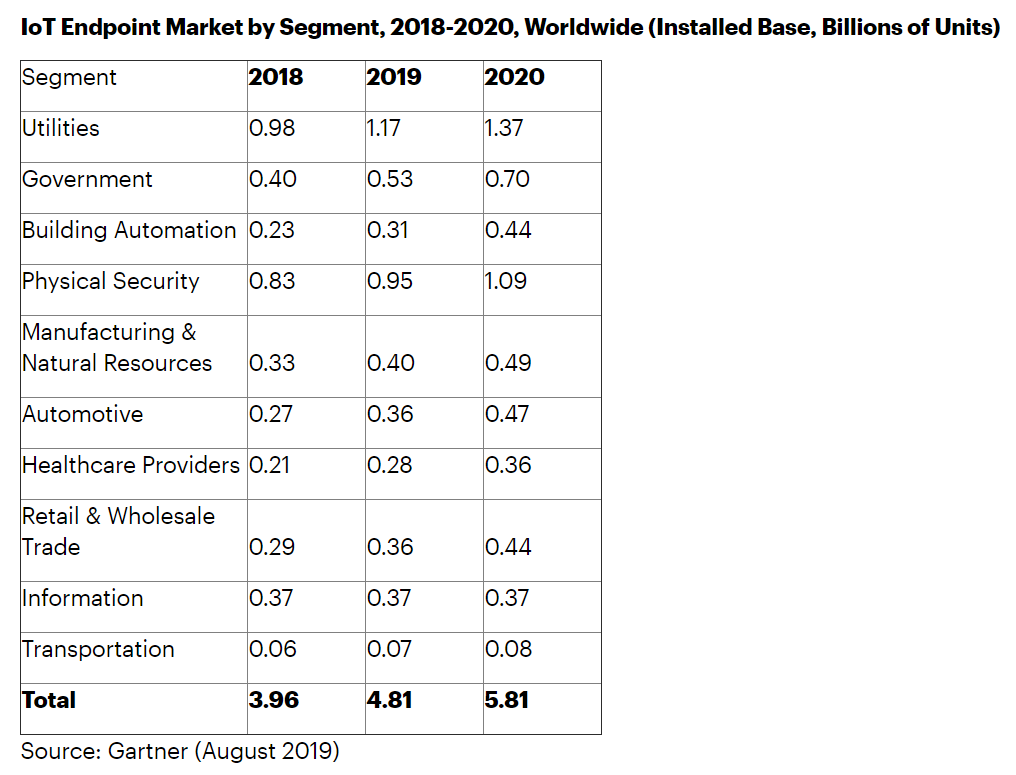

According to Gartner, the IoT is the main driver behind digital transformation. The research organization anticipates there will be 5.8 billion enterprise and automotive ‘endpoints’ in use by 2025.

IoT is used in operations, asset management, and personnel development by manufacturers. It enables the establishment of preventative maintenance programs that can be monitored in real time. It’s also providing a way to improve energy efficiency and working conditions, such as via smart ventilation management, risk management, and worker productivity.

3. Robots

While robots of the future aren’t expected to change drastically from those we see in manufacturing today, they will develop improved learning capabilities based on previous behaviors.

Their ability to use pattern recognition will increase, as will the number of connected devices with which they can interact – and the volume of data they can manage.

Robots are predicted to be particularly innovative in the areas of autonomous driving, carrying and moving, and more. With movement data connected to IT systems and remote teams, this will help drive faster, more efficient business processes and decisions.

4. B2B eCommerce

B2B ecommerce platforms need to react ever more quickly to the needs of B2B buyers, with better checkout processes, pricing rules, and personalization.

They need to offer customers an omnichannel experience with platforms that can automatically sync data and reduce manual inventory management, thereby reducing the risk of human error.

5. Machine learning

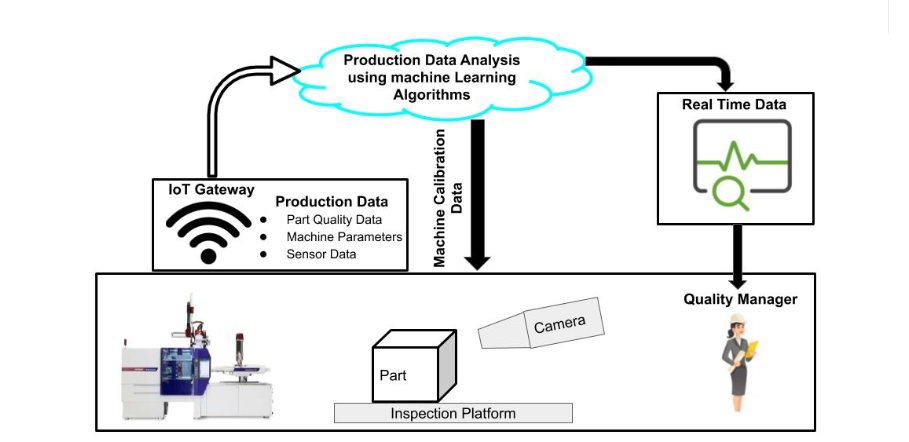

Machine learning can utilize algorithms to analyze data more efficiently than humans and so can choose the best action from a number of potential options. Machines can anticipate more carefully and accurately which factors are likely to impact assembly line speed or quality.

Machine learning can help workers decide on best courses of action by predicting waiting times and shipping times, as well as helping identify potential risk factors in the workplace. Data gathered can give insights into almost all aspects of the production process throughout the supply chain.

6. Cybersecurity

All digital transformations should begin with a plan that includes cybersecurity. This not only helps manufacturers identify and improve security protocols but positions them to manage future risk. Firms need to identify their most critical assets and map how information flows throughout the organization, bearing in mind any new technologies to be onboarded.

This way they will be able to determine the levels of risk involved in terms of lost or compromised information. Then, the company can introduce new roles and procedures to safeguard that data.

Digital transformation is fueling rapid change in manufacturing, from demand and supply to hiring processes involving labor and skill identification. Manufacturers of the future will need to become more agile, and build responsiveness and resilience into manufacturing operations.

They will need to improve their capacity to better manage operations remotely, assisted by emerging digital technologies, so as to reduce the impact of future disruptions.

Author: Sam O’Brien – RingCentral UK

Sam O’Brien is the Senior Website Optimisation & User Experience Manager for EMEA at RingCentral, a Global VoIP, video conferencing and call centre software provider. Sam has a passion for innovation and loves exploring ways to collaborate more with dispersed teams. He has written for websites such as Socialnomics and EffortlessHR.