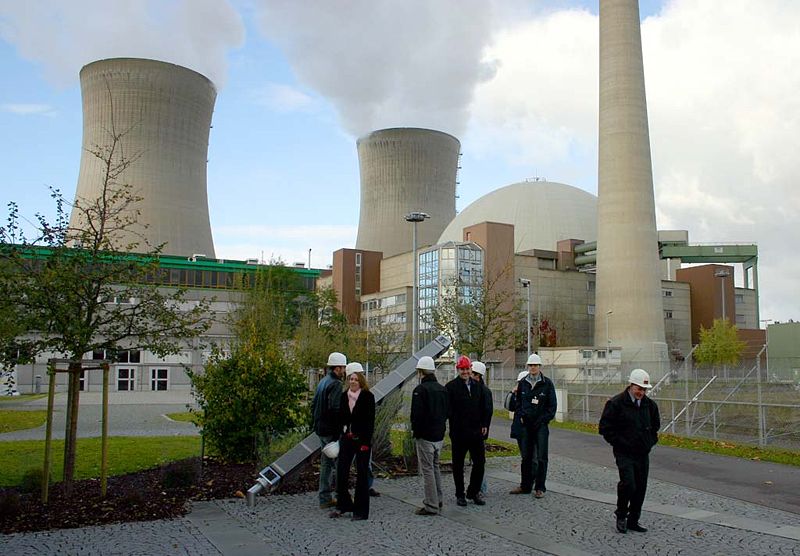

According to a research conducted by Grand View, the global edge computing market will reach a whopping $43.4 billion in terms of valuation by 2027. This translates into a 12X increase when you consider that the global edge computing market was valued at just $3.5 billion in 2020.

Gartner predicts that 75% of all the data enterprises create will be processed at the edge by 2025. Nobody would have expected this type of exponential growth in edge computing especially when you consider only 10% of the data created by enterprises were processed at the edge by 2018. This means that edge computing will replace traditional data centers and even cloud computing in years to come.

We are already seeing shades of this with more than half (57%) of the decision makers pushing for edge computing implementation in the next 12 months. With 5G ready to go mainstream and the internet of things gaining momentum, edge computing will find new applications in different industries. Manufacturing would be one of them.

With factories manufacturing goods and products equipped with state of the art robots, sensors, sophisticated machines and many other connected devices, they are now generating tons of data. All that data could easily go down the drain if you don’t have the right IT infrastructure such as cheap dedicated server hosting and technology such as edge computing to get the best out of it. Implementing an edge computing architecture in a manufacturing environment is no longer a distant dream or far cry. In fact, it has become the need of the hour for manufacturers.

Brian Sathianathan, Chief Technology Officer at Iterate.ai said, “The manufacturing industry continues to push toward edge applications – from robots scurrying around the warehouse to acoustic calibrators to cameras identifying faults on the manufacturing line – to advance factory automation and efficiency. The challenge for CIOs in this industry is how to put the power of edge systems into place while ensuring edge applications stay always-on and don’t wreak havoc on their networks.”

In this article, you will learn about four applications of edge computing in the manufacturing industry.

4 Edge Computing Applications For Manufacturing Industry

Here are four use cases of edge computing in the manufacturing industry.

1. Warehouse Automation

Automation is no longer separate from manufacturing. In fact, it has become so ingrained into modern manufacturing processes that it is hard to distinguish between the two. Managing your warehouses and ensuring efficient inventory management is imperative for business success. Edge computing can help you achieve that goal with warehouse automation.

Technologies like computer vision can help you keep track of inventory levels while bluetooth low transmission energy and RFID technologies can be used to identify the exact location of the item in the warehouse. Computer vision can also play a crucial role when it comes to product picking.

If you are using smart shelves to store items, it can automatically notify you when an item is about to go out of stock or its inventory decreases below a certain level, thanks to smart sensors embedded inside them. Collecting all that data from all those technologies and sending it back to the cloud or traditional data centers for processing is not the most sensible option.

That is where edge deployments can come in handy. It is not only more cost effective, secure and delivers lower latency, just like a VPS Singapore. It also gives you more flexibility and options to choose from, which makes it a worth considering option.

2. Quality Assurance and Automation

Another facet where automation plays a crucial role is in quality control and quality assurance. Depending upon the maturity level of the manufacturer and its urge to adopt new technology, manufacturing facilities could have little to no automation or fully automated facilities powering their manufacturing processes.

Implementing edge solutions and IoT devices and sensors might be a good option if your business is mature enough and moving towards fully automated manufacturing. It might not be the best option for businesses who are in the initial stage. stages of their automation journey.

Never rely on just one technology like a cheapest dedicated server , always diversify. Use a combination of technologies for automation. For instance, you can combine the power of computer vision, IoT sensors and machine learning for the best results. Store the data as close as possible so it can be accessed quickly and it is only possible with edge computing. Quality control automation is already being used in packaging and canning by the beverage industry and food industry.

3. Production Line Diagnostics

A manufacturing facility could have hundreds of different machines and each machine has hundreds of different parts. Issues with any of these parts can stop machines from performing their jobs which could disrupt the entire production process. As a business, you don’t want that. Keeping track of all these bits and pieces is not easy, especially when you are doing it manually. You can easily overcome this problem with predictive analytics and machine learning.

These technologies can help you predict issues with any of the parts so you can take corrective measures before the issue can stop the production lines. This minimizes the downtime and increases productivity and efficiency. Any small delay can cost you thousands of dollars and these technologies can prevent that. By integrating these technologies in quality assurance and control processes, you can reap the real benefits of these technologies.

4. Product Tracking and Logistics

Probably the biggest advantage of implementing edge computing in manufacturing is that it gives you full control over manufactured products even when it gets out of your factory and moves through different stages of the supply chain. RFID and BLE technologies can be used to track products even if they are in pallets and crates or even when they are inside the shipping containers. Businesses can scan trucks when they enter into the warehouse or when they move out of the warehouse to ensure consistency between input and output production levels. This means that the boundary of the edge will expand regularly, giving you more control.

How do you implement edge computing in the manufacturing industry? Let us know in the comments section below.

Author bio : Jennylain a qualified professional at Hostnoc with ground-breaking experience in developing SEO campaigns, analytics, and monitoring the ranking in Google search pages. A clear communicator with an experience of digital marketing and improving brand search ranks.