The energy industry, perhaps the largest and most powerful in human history, has forged new technologies at a breakneck pace over the decades. These technologies have been forged in a crucible of high demand for oil and its byproducts and dangers associated with volatile substances.

Energy producers and suppliers have been some of the busiest enterprises over the past half century. Companies in these sectors have complex industrial operations that today require rapid prototyping, tooling, and additive manufacturing (AM).

Additive Manufacturing Transforming Manufacturing

According to a recent Deloitte report, “3D Opportunity: Additive Manufacturing Paths to Performance, Innovation, and Growth,” additive manufacturing technology has emerged after nearly 30 years of development and will transform manufacturing over the next decade.

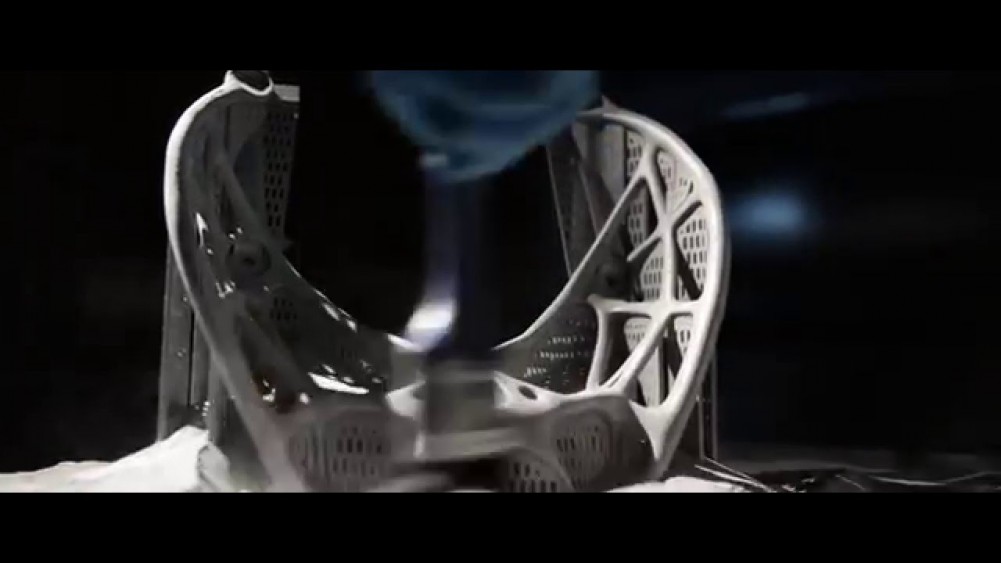

According to the American Society for Testing and Materials (ASTM), “additive manufacturing is a process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies.”

3D Systems, A Leader in Additive Manufacturing

3D Systems has provided a full range of advanced solutions in design and advanced manufacturing, especially in creating certified facilities and technology for aviation, aerospace, and defense. The company has perfected “on demand” parts manufacturing in order to quickly solve complex manufacturing problems.

A relatively new area of manufacturing for 3D Systems is precision healthcare solutions such as patient-specific device design and certified healthcare facilities.

The following video shows the Lotus F1, which has partnered with 3D Systems.

The following video shows how General Motors and 3D Systems have worked together.