Berlin, Germany/Los Angeles, U.S.A., [November 7, 2023] —1000 Kelvin, the Berlin/Los Angeles-based startup at the forefront of AI solutions for metal and polymer 3D printing technology, is thrilled to announce the full commercial availability of its AI-driven software, AMAIZE, at Formnext 2023. The company is also unveiling its first integrations with commercial 3D printer manufacturers—including EOS—and customers, including a California-based rocket launch provider.

Omar Fergani, Ph.D., Co-founder and CEO of 1000 Kelvin, stated, “The manufacturing and production sector accounts for one-fifth of global carbon emissions and 54% of the world’s energy usage. 3D printing has the unique ability to address these issues, but not until it works consistently. By improving the efficiency and reducing the waste associated with 3D printing, while making the technology easier to use, AMAIZE contributes to a more sustainable future.”

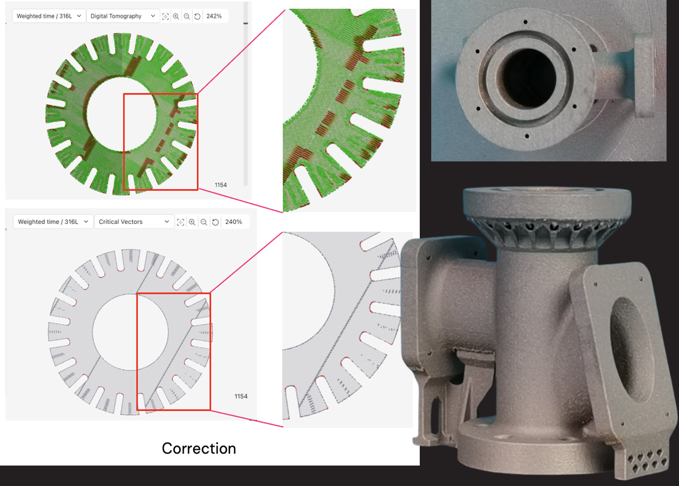

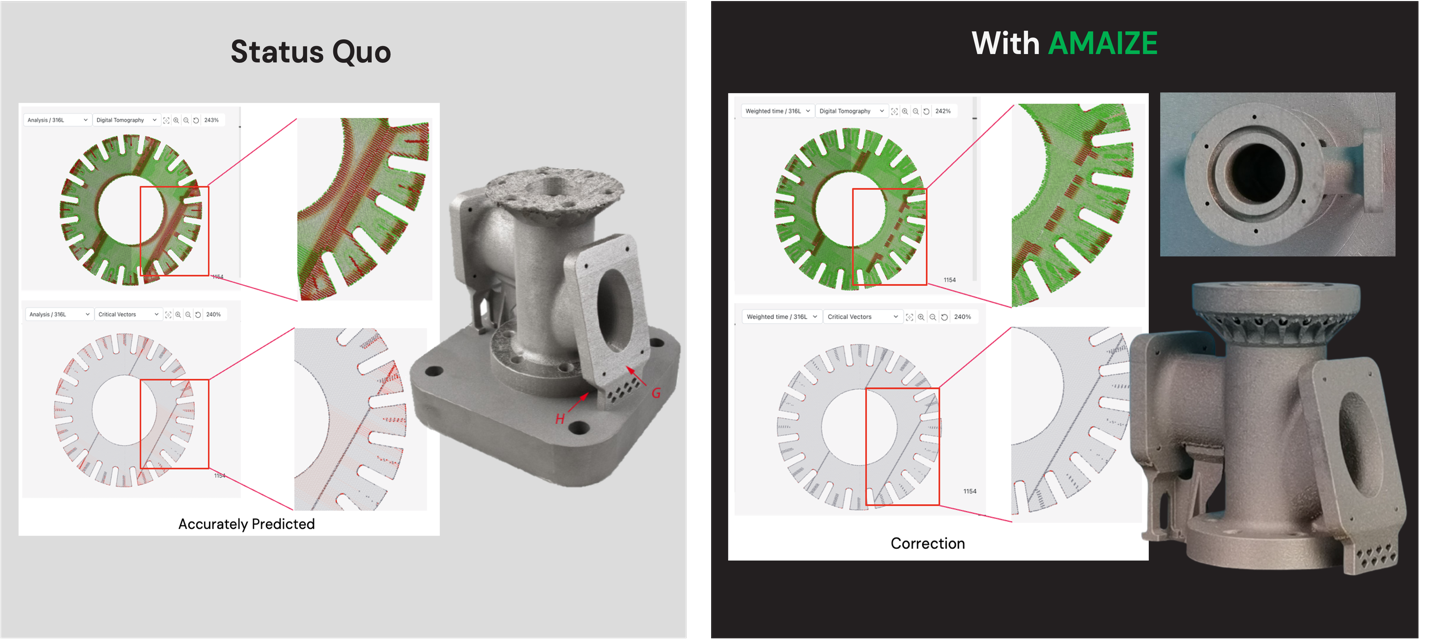

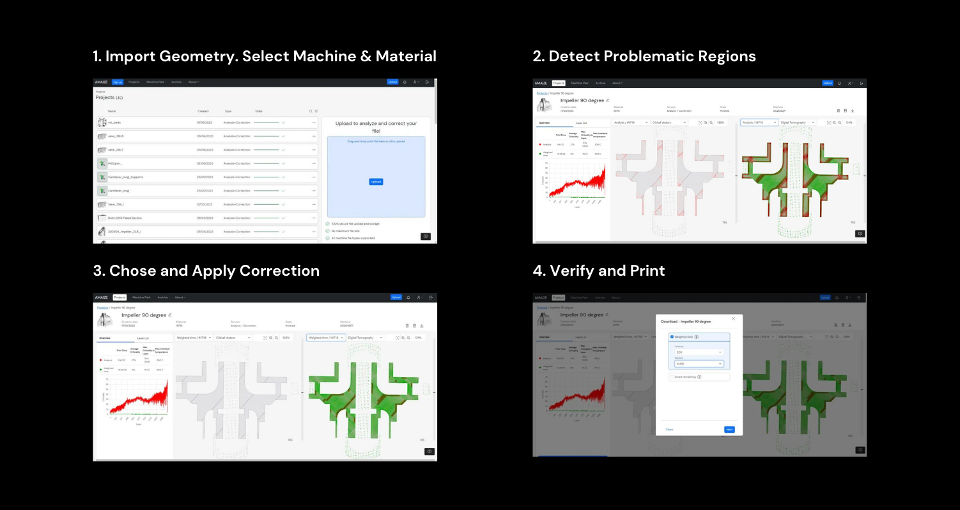

AMAIZE enables the generation of optimal print recipes using a physics-informed AI technology for first-time-right 3D printing. Users upload a print file to the AMAIZE cloud, which analyzes the part and automatically corrects thermo- mechanical issues by optimizing the scan strategy and process parameters. This eliminates the need for costly finite element simulation software and multiple physical iterations, which result in wasted materials, energy, and money.

1000 Kelvin has already directly integrated the cloud native solution AMAIZE with multiple machine OEMs enabling next generation AI- software and compute infrastructure for additive manufacturing. As a result of successfully concluding its early adoption program, AMAIZE has already been adopted by companies in the energy, aerospace, and contract manufacturing industries. One example is a California-based rocket launch provider, who faced significant challenges in 3D printing a critical part. The issues stemmed from print failure due to overheating and substantial reduction of support structures, leading to inefficiencies and delays.

By leveraging AMAIZE, the company was able to digitally iterate solutions to these thermal management problems. The result was a successfully printed part with improved surface quality and performance. Notably, AMAIZE enabled the customer to reduce support structures by over 80%, leading to a more than 30% reduction in the overall cost per part when considering both saved material and post-processing costs. This case study exemplifies how AMAIZE’s focus on tackling the root cause—thermal management—can significantly accelerate time to market.

1000 Kelvin has so far secured $3 million in funding, which has allowed it to grow beyond Europe and establish a presence in Los Angeles, California to cater to its clients in the aerospace and defense industry.