3D printing can revolutionize traditional manufacturing industry just like PC revolution in the last century and mobile communication most recently. The idea behind 3D printing is to speed up the production, cut down the production costs and be easier to use.

Today, we all are familiar with 3D printers that can print objects only from plastic materials.

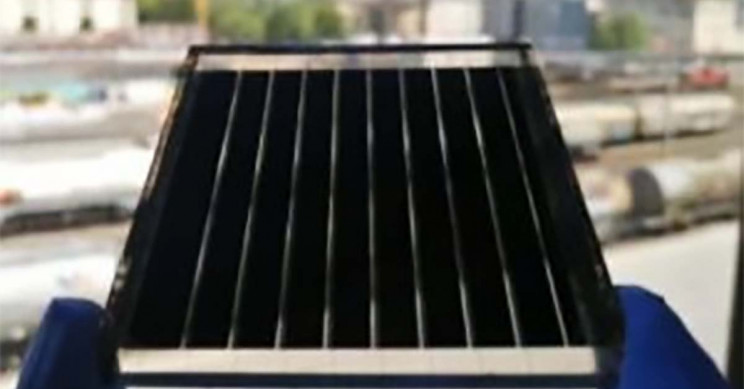

Mark One 3D printer produces carbon fiber parts five times stronger than ABS

The Mark One 3D printer raises the bar even higher by overcoming the strength limitations of traditional 3D printed materials. It offers a potentially revolutionary technology that can make all those ordinary 3D printers feel more like dot matrix technology by printing objects stronger than 6061-T6 aluminum.

Developer Gregory Mark, of MarkForged, unveiled his first working prototype of the world’s first carbon fiber 3D printer at SolidWorks World 2014 in San Diego recently. The printer can print in carbon fiber, fiberglass, nylon and PLA and can generate extremely stable, lightweight objects. Carbon fiber is 20 times stiffer and five times stronger than ABS plastic with a strength that exceeds steel.

This 3D wonder will be available soon

At $5,000, the Mark One printer is slightly more expensive than a normal 3D printer. The first commercially available 3D printers will be available for pre-order starting next month, with the earliest shipping date estimated in the second half of 2014.