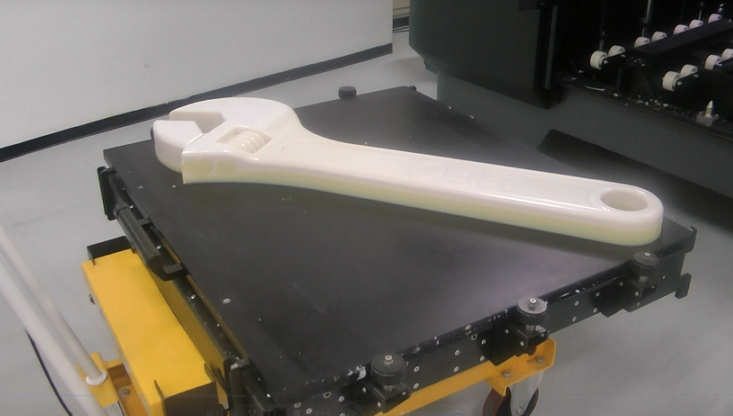

It’s only natural that following the huge global interest in 3D printed wrenches, that I’d immediately print the largest wrench we’ve ever made using the new Objet1000 wide format 3D printer that we released at last week’s Euromold.

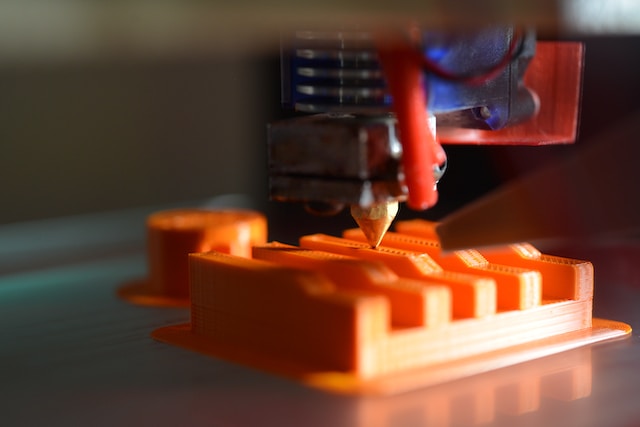

As you can see from the video above, the Objet1000 features a very user-friendly hand-cart and roll-on/roll-off build tray that enables you to easily move your big models from the 3D printer to the custom-built washing system that removed the support material.

The process is fast, easy and only uses a water-jet. Once the support material is dislodged from under the wrench the enormous prototype model can then be picked up and tested.

The entire post-process from the final print layer to actually holding your finished prototype doesn’t take more than about ten minutes of work.

To compare how this wrench sizes up to the “second largest” wrench previously printed on the Objet Connex500 system – see this video. And just in case you were wondering – yes you can print the giant wrench in the green ABS-like Digital Material on the Objet1000 system to achieve the functional performance of engineering plastic.

Check out the source.