Experimenting with new material has become more common of late in bicycle manufacturing, with the aim of creating lighter but more durable parts to your bicycle. This is where Kettle Cycles’ SiCCC brake rotor enters.

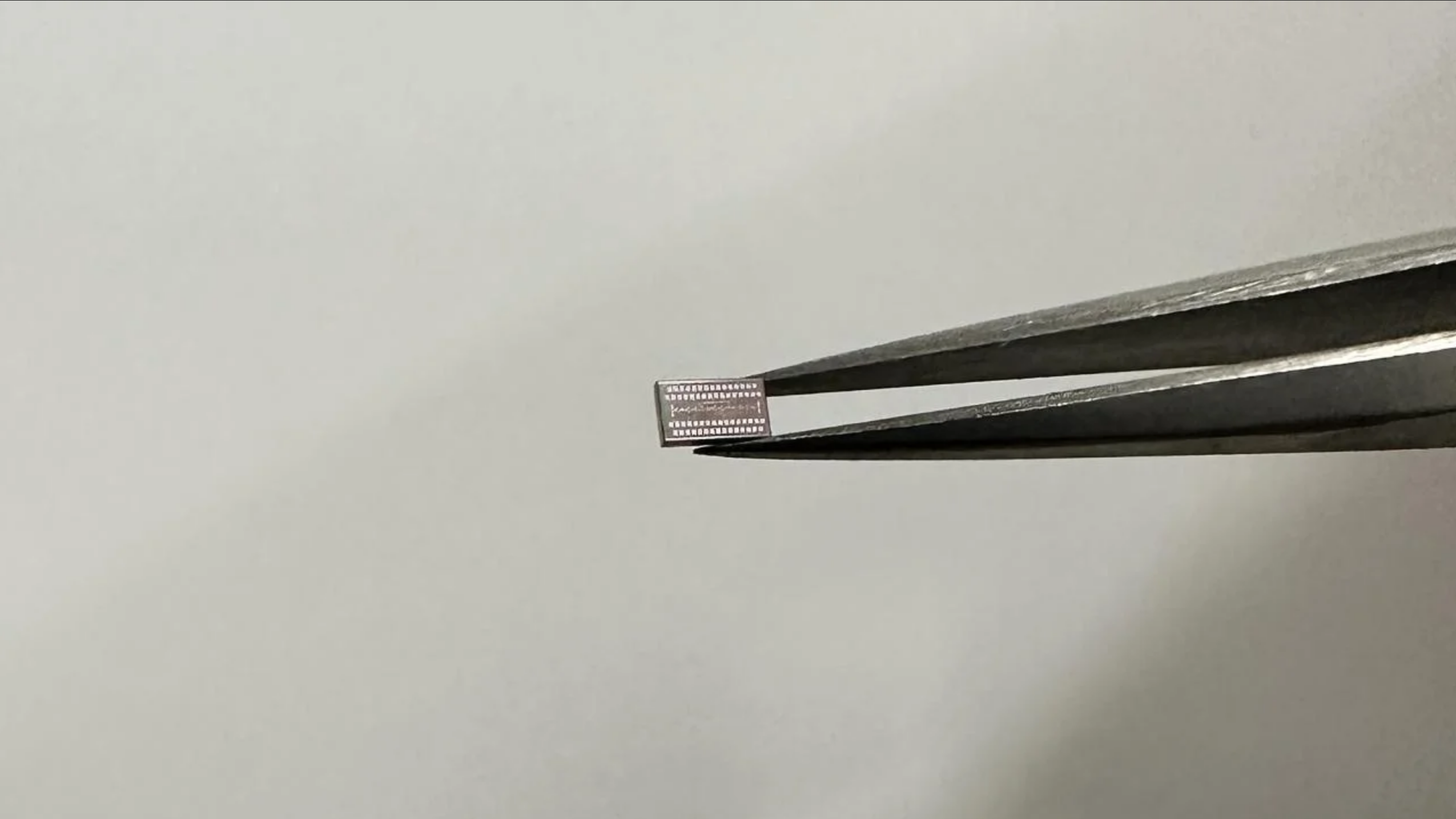

Light weight, wear resistant, higher coefficient of friction, and more sustainable heat management are just a few of the key features designed by Kettle with their new brake rotor. The rotor’s make up of material is what makes it truly unique though, with its combination of Silicon Carbide with Ceramic and Carbon. Due to the non-metallic composite material, the SiCCC rotor doesn’t expand or contract like your standard metal bike rotors, nor will it distort in shape due to ‘stress’ or overuse. Despite all these features, the SiCCC rotor is, in fact, lighter too and won’t be adding unnecessary weight to your bicycle.

“Our goal from the start was to create a more consistent, better wearing, lighter weight brake rotor. The results are reliable, progressive braking – hot or cold, wet or dry, no excuses,” explains Josh Gore, co-founder of Kettle Cycles.

“Not only does our SiCCC rotor brake well but it’s extremely strong. The same strength applies not only to impact but also wear and best of all – they’re around half the weight of current high end brake rotors.”

The SiCCC rotor is compatible with virtually all bicycle models, which makes it a little more desirable for cyclists in search of something that’s much more durable and long lasting.