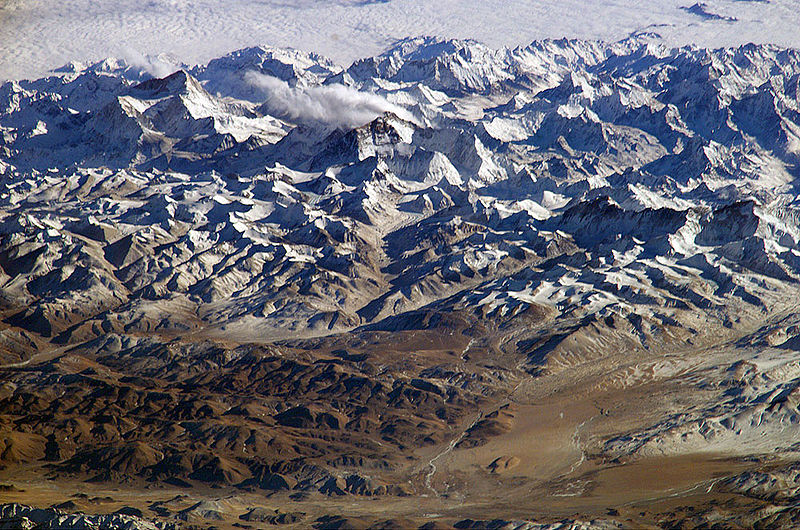

Say goodbye to fiberglass and plastic insulation rolls and hello to an all-natural insulation made out of mushrooms. Launched in 2009, Ecovative Design has discovered a way to harness the insulating powers of Mycellium; Mycellium is a root that produces the Armillaria solidipes mushroom found in the Blue Mountains of Oregon.

This root can hold up to 30,000 times its own weight, is flame resistant, termite proof, and completely biodegradable. It can also be produced in a lab in 3-days time, making it environmentally responsible because it requires just a fraction of the cost as alternative insulators.

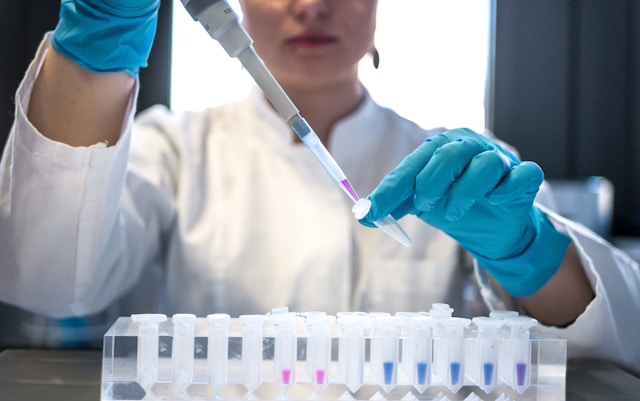

Mycellium insulation is produced using agricultural waste such as rice hulls and food stock–products that humans and animals are unable to digest.

The Mycellium roots spread out among the rice hulls and food stock and metabolize and bind the product together creating insulation foam. When installed, the foam will expand behind the dry wall and completely fill up empty space for about a month before becoming air sealed and dormant.

To answer your question, this root will not sprout any mushrooms spores unless there are flaws or gaps in the initial structure, and even then, the mushrooms spores can be cut off using scissors or a knife without harm.

When it comes time to replace the insulation, it can be thrown away and will eventually return to the earth as soil without causing environmentally hazardous carbon emissions. This new insulation design by Evocative Design represents ecological innovation and helps to advance the a rising interest in “Green Construction” and biotechnology. The firm has already designed a Mushroom Tiny House to prove its point.