In a big breakthrough, Penn engineers have developed a “self-healing” metal.

Metal being very strong material is used for thousands of years to make various things. When it is damaged, lot of energy is required to repair it. Now researchers from University of Pennsylvania have developed a new technique that has made it possible to repair metal at room temperature. Since the technique is quite similar to how the bones heal, the engineers call their technique “healing”.

“Self-healing” metal:

Usually, for repairing metal, we need to melt it with welding torches that can reach 6300 °F. However, this innovative research published in the journal Advanced Functional Materials, exhibits quick, effective and room‐temperature healing of metallic materials.

In some metals, melting metal to repair it is not a viable option. For example, the metals made with internal pockets of air, melting removes their complex internal structure. While researching for ways to repair such porous materials, researchers came across the self-healing materials that are developed using softer polymers and plastics.

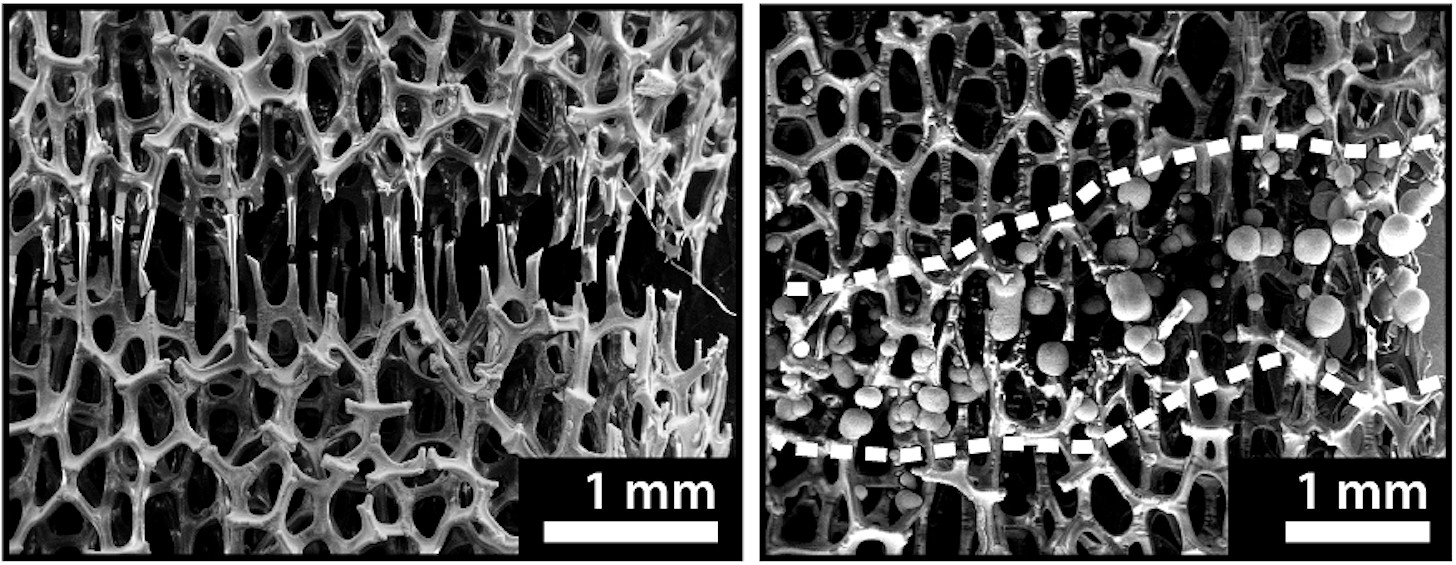

Electrochemistry adds new metal just to the broken struts, reconnecting them and “healing” the damage. (Image courtesy: Pikul Research Group)

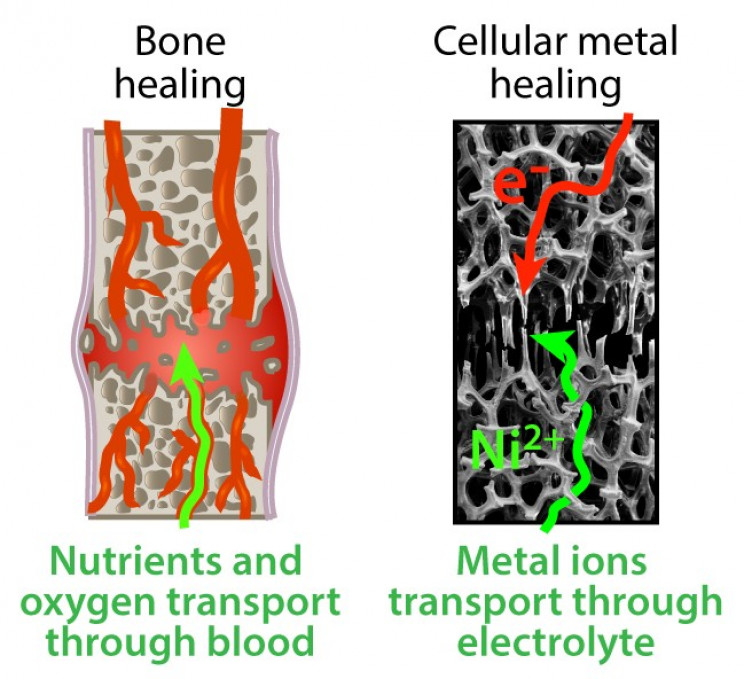

Researchers used electrochemistry and polymer‐coated cellular nickel to mimic the transport‐mediated healing of bone.

James Pikul assistant professor in the Department of Mechanical Engineering and Applied Mechanics at the University of Pennsylvania said “I think most people would say bone is a self-healing material and I think, in practice, our material is very similar to bone. Bone is not fully self-contained either; it needs an energy source and nutrients to heal, both of which come from eating food. In our system, these function similarly to the voltage and electroplating bath.”