3D printing has generated insane levels of hype and seems to be a major discussion topic on social media, but is it warranted?

Industries such as the Rapid Product Development are raving about the convenience and productivity boost where a prototype for a new product can be printed out on your desk within hours of design. It turns out that, yes, the hype is warranted in the product development industry.

But what about practical uses for 3D printed components in industrial applications?

For example, can we print out a part to be used as a replacement part on the factory floor? Instead of a stock room filled with hundreds of spare parts, is it possible to replace all surplus stock with a 3D printer and 3D files?

These questions led us on a discovery to find practical uses of 3D printed parts. Very quickly, we found two companies who helped us further understand the viability of 3D printed parts in industrial manufacturing.

Are 3D printed parts ready for industrial applications?

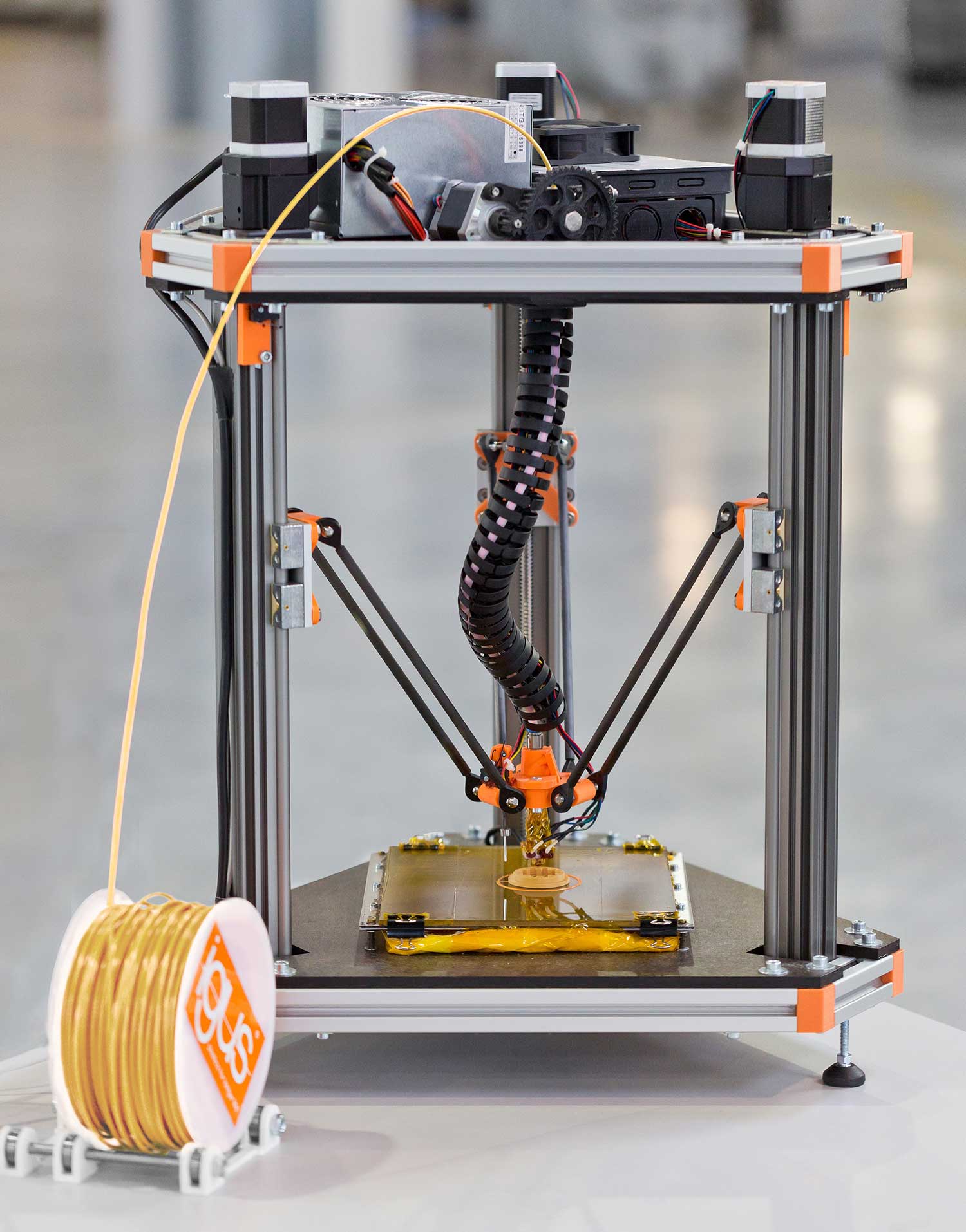

Up-and-coming technology, 3D printing provides a better way to print full-size, three-dimensional objects and reduces the high tooling costs of part production, eliminates waste and prints only the desired object for additional production savings.

Essentially, with the proper computer software, any printed component can be customized to the exact shape and size desired, making otherwise impossible-to-find parts available and affordable.

With today’s advancements in 3D printing technology, it is feasible to print models, guitars, clothing, food, product development models and even houses.

This past week, I spoke with a few companies who have installed 3D printers to print replacements parts.

One company sells automation parts and is now printing obsolete plastic parts that are no longer in production. The company utilizes a scanner that scans an in-stock part to create a 3D file and then print out brand new parts.

The second company is the leading manufacturer of Plastic Bearings, igus, who designated a team to develop a 3D printer filament (the material used to print a part). Filament is typically plastic that is heated up and then deposited in layers to build up a part.

After a lot of hard work, igus recently introduced the world’s first plastic filament for 3D printers enhanced with tribological, or low friction, properties. The new material is ideally suited for creating custom bearings and, incredibly, is 50 times more resistant to wear and abrasion than conventional 3D printer materials!

This exciting new product, which has already completed countless tests in the igus test lab, is the first filament for 3D printers specifically developed for motion control applications.

Now, igus continues to research filaments for 3D printers in order to provide customers with more flexibility in their design ideas. For example, customers can design custom parts or manufacture prototypes, while still being able to rely on the dependable, tested service life of igus plastic materials.

Still, even with the success of one company, one major question remains…

Is the 3D printed quality comparable to a factory manufactured plastic bearing?

Typically, factory made bearings are higher density and can be manufactured to a higher tolerance.

But that’s just for now.

We are at the beginning of the 3D revolution, with 3D printing improving every year, getting faster and producing higher quality parts and products as development continues to climb.

Harold Sears, Ford additive manufacturing technical specialist, says, “Many have referenced this technology as ushering in a third industrial revolution. While that is yet to be determined, what we do know is manufacturing is continuing to go digital, the speed of these technologies is increasing and the variety of materials is expanding – all of which leads us to believe 3D printing presents a great opportunity for overall manufacturing.”

Applications where 3D printed plastic bearings are perfect are:

- Food

- Military

- Electronics

- Toys

- Industrial Manufacturing

- Aerospace

- Automotive

- Medicine & Healthcare

- Art